您当前的位置:首页>论文资料>U形支架弯曲工艺优化及模具改进设计

内容简介

模具技术2017.No.2

模具技术2017.No.2文章编号:1001-4934(2017)02-0037-02

U形支架弯曲工艺优化及模具改进设计

张党华

(江西江铃底盘股份有限公司,江西抚州344000)

37

摘要:原U形支架弯曲模生产的U形支架两侧折边表面存在拉痕、划伤等缺陷,下模使用寿命短。通过优化U形支架弯曲工艺及改进弯曲模具结构,引入轴承滚针,成功地解决了缺陷问题,并推广至其他规格的U形支架弯曲模中应用,提高了产品外观质量,降低了生产成本。最后通过实践验证,总结归纳了轴承滚针结构弯曲下模结构尺寸并标准化。

关键词:U形支架;弯曲;拉痕;轴承滚针

中图分类号:TG386

文献标识码:B

Optimization design of bending process and the die improved design for U-shaped bracket

ZHANGDang-hua

Abstract: In the U-shaped bracket bending process, there arc pull marks, scratches and oth-er defects on both sides of the U-shaped bracket flanging surface, and the life of bending dic is short. In order to solve the issucs of appearing surface defects such as drawing stamps and scratches in the bending process, a bearing ncedle structure has been introduced in the process of optimization design of bending process for U-shaped bracket. Such technology can be extended to bending dies of other specification U-shaped bracket, which can improve the appearance of the product quality and reduce production costs. Also, the design sizes of the bearing needle which were summarized and recommended in this paper can be referred for the peers in their further design project.

Keywords:U-shaped bracket;bend;pull marks;bearing ncedle

的Q235酸洗板材,外观要求光滑、美观。

零件分析 1

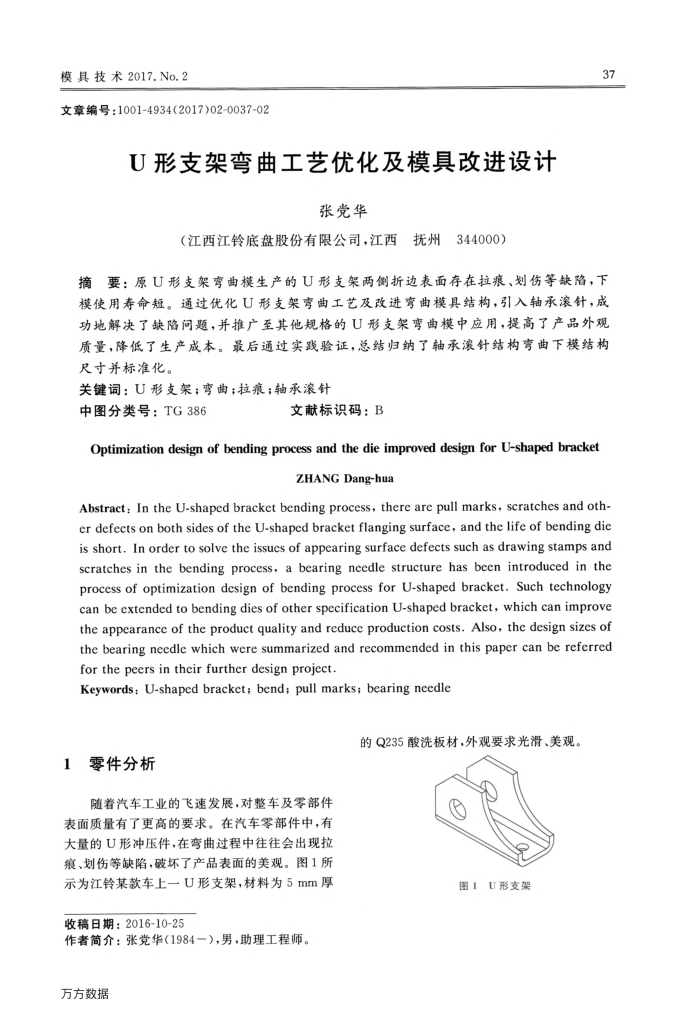

随着汽车工业的飞速发展,对整车及零部件表面质量有了更高的要求。在汽车零部件中,有大量的U形冲压件,在弯曲过程中往往会出现拉痕、划伤等缺陷,破坏了产品表面的美观。图1所

示为江铃某款车上一U形支架,材料为5mm厚收稿日期:2016-10-25

作者简介:张党华(1984一),男,助理工程师。万方数据

图1U形支架