您当前的位置:首页>论文资料>某型号柴油机零件衬套软氮化工艺研究

内容简介

第38卷(2016)第2期工艺与材料

第38卷(2016)第2期工艺与材料柴油机 Diesel Engine

Vol.38(2016)No.2

某型号柴油机零件衬套软氮化工艺研究

王东军,马天帅,赵瑞

(海军驻大同地区军事代表室,山西大同037036)

摘要:针对某型号荣油进排气挺柱部件村套软氮化后,因没有考虑其变形,而直接装配使用,造成该部件工作过程中卡死,导致荣油机发生故障的问题,从衬套软氮化主要工艺参数着手,研究软氨化工艺参数对村套表面白色化合物(耐磨层)深度及衬套变形的影响规律。根据研究结果改进

了软氮化工艺参数,并结合调整机械加工工艺,使该零件的变形问题得到控制。关键词:荣油机;村套;软氮化;工艺

中图分类号:TK426

文献标识码:A

文章编号:1001-4357(2016)02-0045-03

The Study of Tufftriding Technics of Parts Bush in Certain Model Diesel Engine

Wang Dongjun,Ma Tianshuai,Zhao Rui

(Naval DeputyOfficeof DatongDistrict,Shanxi Datong 037036)

Abstract: After the tufftriding processing of the bush of the intake and exhaust valve tappet, the part was stuck during the working process, which led to the fault of the diesel engine, for directly using without taking the deformation into consideration. Based on the major technics parameters of the tufftriding of bush, the influence of certain parameters on the depth of white chemical compound ( abrasion resistant layer) and the deformation of bush were analyzed. The technics parameters of tufftriding were improved according to the results, and being accompanied of the modification of the machining technics, the de formation of the part was kept under control.

Key words: diesel engine; bush; tufftriding; technics

0引言

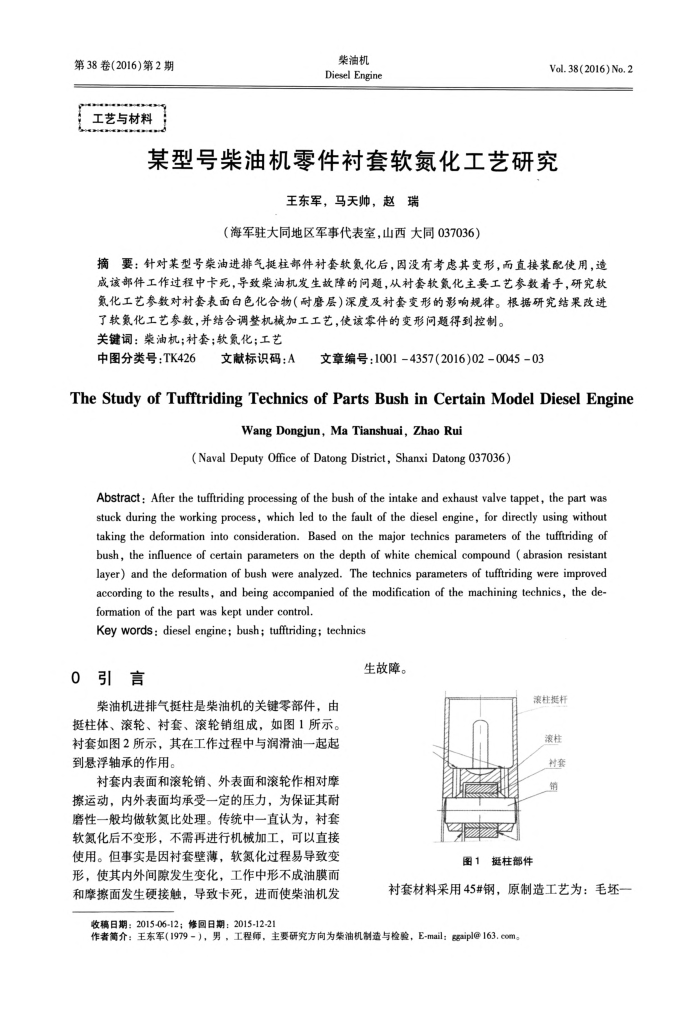

柴油机进排气挺柱是柴油机的关键零部件,由挺柱体、滚轮、衬套、滚轮销组成,如图1所示。衬套如图2所示,其在工作过程中与润滑油一起起到悬浮轴承的作用。

衬套内表面和滚轮销、外表面和滚轮作相对摩擦运动,内外表面均承受一定的压力,为保证其耐磨性一般均做软氮比处理。传统中一直认为,衬套软氮化后不变形,不需再进行机械加工,可以直接使用。但事实是因衬套壁薄,软氮化过程易导致变形,使其内外间隙发生变化,工作中形不成油膜而和摩擦面发生硬接触,导致卡死,进而使柴油机发

生故障。

激柱挺杆滚柱持套

图1挺柱部件

衬套材料采用45#钢,原制造工艺为:毛坏一

收稿日期:2015-06-12;修回日期:2015-12-21

作者简介:王东军(1979-),男,工程师,主要研究方向为案油机制造与检验,E-mail:ggaipl@163.com。

上一章:某型大功率柴油机负荷限制原因分析

下一章:液态燃料跨∕超临界喷射研究进展