印涂铝盖冲压拉深凹模圆角的数值模拟优化设计

内容简介

第41卷第12期 Vol. 41No.12

第41卷第12期 Vol. 41No.12饭

压技

FORGING & STAMPING TECHNOLOGY

印涂铝盖冲压拉深凹模圆角的数值模拟优化设计

鲜小红',2

2016年12月 Dec.

2016

(1.四川大学制造科学与工程学院,四川成都610065:2.四川职业技术学院机械工程系,四川遂宁629000)

摘要:以非线性有限元分析软件Dynaform为平台,将1716印涂铅董坏料在不同因角的凹模上的冲压拉深过程进行了数值税拟,通过对比分析数值模拟结果,确定了1716印涂铅董冲压拉深回模角的相对合理尺寸。该方法大幅度降低了模具调试的难度,缩短了模具设计制造周期,减少了1716印涂铝盖产品的生产成本。1716印涂铝盖首次拉深件质量相对优化的回模圆角取值范围为:R,=2mm和1R,-2mm1一→0。综合考患1716印涂铝董的精度要求和机床的加工精度,确定选择R,=2mm 为1716印涂错盖首次拉深回模圆角的相对合理工艺参数,

关键词:印涂错盖;冲压拉深;Dynaform;凹模圆角;模具调试 DOI: 10. 13330/j. issn. 1000-3940. 2016. 12. 029

中图分类号:TG386.3*2

文献标识码:A

文章编号:1000-3940(2016)12-0165-05

Simulationand optimization design ondrawing diefilletforprintedand

coated aluminium covers

Xian Xiaohong'.2

(1. Manufacturing Science & Engineering Collegr, Sichuan Univernsity , Chengdu 610065, China; 2. Department of Mechanical

Engineering, Sichuan Vocational Technical College, Suining 629000, China)

Abstract : The drawing process of 1715 printed and coated aluminium covers with different die fillets was simulated by the nonlinear finite element analysis software Dynaform, and the relative reasonable die fillet was confirmed by comparing simulated results. Therefore, the difficulty in die debugging was reduced greatly, and the design period was shortened, as well as the production costs were reduoed. The optimal die fillet of the first drawing was R, = 2 mm and 1 R, 2 mm I → 0 respectively. After comprehensive considerations on the pre-cision requirements of 1716 printed and coated aluminium cover and manufacture precision of machine tools, R, =2 mm was regarded as the most reasonable process parameter.

Key words : printed and coated aluminium covers; deep drawing; Dynaform; die fillet; die debugging

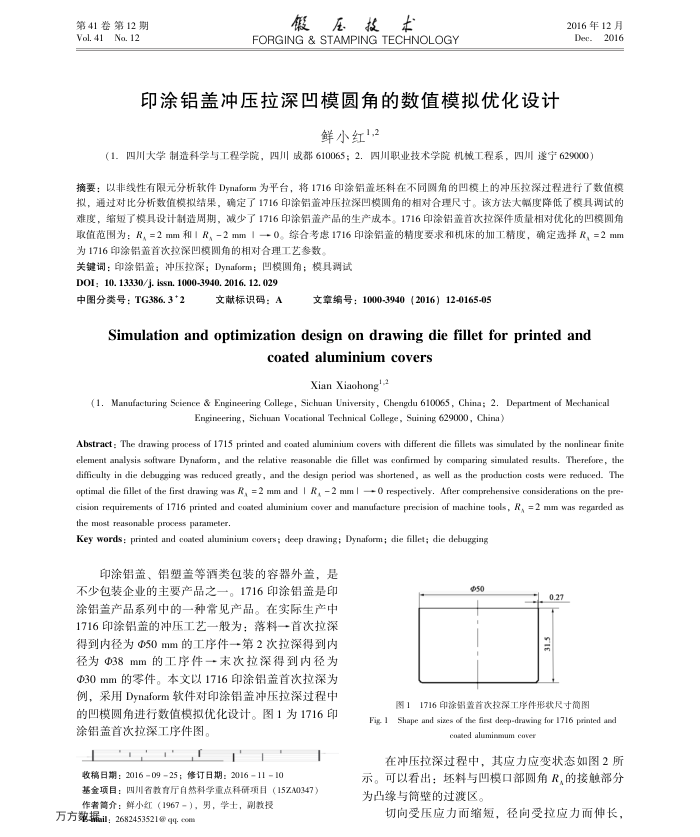

印涂铝盖、铝塑盖等酒类包装的容器外盖,是不少包装企业的主要产品之一。1716印涂铝盖是印涂铝盖产品系列中的一种常见产品。在实际生产中 1716即涂铝盖的冲压工艺一股为:落料一→首次拉深得到内径为@50mm的工序件一第2次拉深得到内径为@38mm的工序件一→末次拉深得到内径为@30mm的零件。本文以1716印涂铝盖首次拉深为例,采用Dynaform软件对印涂铝盖冲压拉深过程中的凹模圆角进行数值模拟优化设计。图1为1716印涂铝盖首次拉深工序件图。

收稿日期:20160925;修订日期:20161110

基金项目:四川省数育厅自然科学重点科研项目(15ZA0347)

作者筒介:鲜小红(1967-),男,学士,副教授万方数据il:2682453521@q.com

Fig. 1

050

0.27 SIE

1716印涂留盖首次拉深工序件形状尺寸简图

图1

Shape and sizes of the first deep-drawing for 1716 printed and

coated aluminmum cover

在冲压拉深过程中,其应力应变状态如图2所示。可以看出:坏料与凹模口部圆角R,的接触部分为凸缘与筒壁的过渡区。

切向受压应力而缩短,:

径向受拉应力而伸长,

上一章:汽车后围板拉深成形过程中的回弹预测

下一章:覆盖件修边镶块随形曲面的优化处理方法