您当前的位置:首页>论文资料>拉深筋对板料成形回弹影响研究

内容简介

20

20模具工业2014年第40卷第12期

拉深筋对板料成形回弹影响研究

李军,王晓枫

(合肥工业大学机械与汽车工程学院,安徽合肥230009)

摘要:利用Dynaform软件,对某车型右前侧车门铰链加强板三维模型进行数值模拟,重点对板料成形质量中不等裁面拉深筋的影响进行分析,通过改变不等截面拉深筋的拉深阻力来改善板料的成形质量,得出合理的拉深筋参数。根据不等截面拉深筋阻力的大小和分布情况,通过拉深阻力模型来对拉深筋儿何参数反求,获得不等截面拉深筋的实际分布情况。比较不同拉深阻力的回弹结果,得出最有效的控制回弹的方法是不等截面拉深筋。

关键词:铰链加强板;拉深筋;几何参数;成形;回弹

中图分类号:TG386:0242.21

文献标识码:B

文章编号:1001-2168(2014)12-0020-05

Study on the effect of reinforcement rib on the springback

of sheetmetalforming LI Jun, WANG Xiao-feng

(School of Mechanical and Automotive Engineering,Hefei University of Technology, Hefei,

Anhui 230009,China)

Abstract: The numerical simulation was made on the 3D model of a front right door hinge reinforcing plate by Dynaform; and the analysis was in particular on the effects of nonuni-form cross section of reinforcement rib on the sheet metal forming quality. The sheet met-al forming quality was improved by changing the reinforcement rib resistance and the opti-mized reinforcement rib parameters.The actual distribution situation of nonuniform cross section of reinforcement rib was achieved according to the value and distribution situation of the reinforcement rib resistance and through reverse engineering the reinforcement rib geometric parameters based on the drawing resistance model. By comparing different draw-ing resistance of springback results, it was concluded that the best method to control the springback is nonuniform cross section of reinforcement rib

Key words: hinge reinforcing plate; reinforcement rib; geometric parameters; forming; spring-back

引言 1

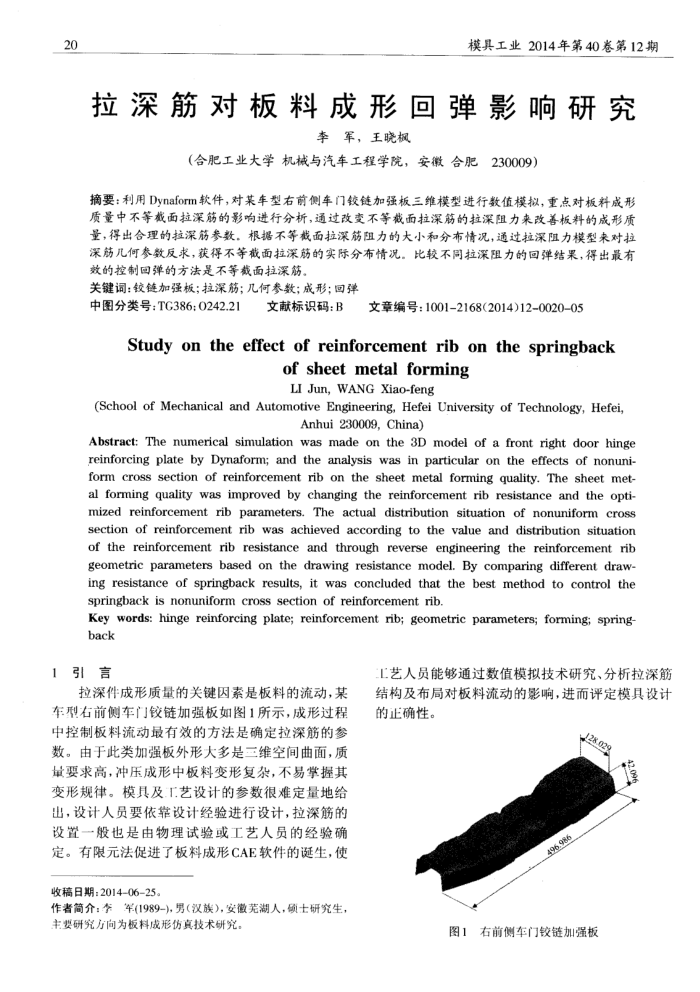

拉深件成形质量的关键因素是板料的流动,某车型右前侧车门铰链加强板如图1所示,成形过程中控制板料流动最有效的方法是确定拉深筋的参数。由于此类加强板外形大多是三维空间曲面,质量要求高,冲压成形中板料变形复杂,不易掌握其变形规律。模具及T艺设计的参数很难定量地给出,设计人员要依靠设计经验进行设计,拉深筋的设置一般也是由物理试验或工艺人员的经验确定。有限元法促进了板料成形CAE软件的诞生,使

收稿日期:201406-25。

作者简介:本车(1989-),男(汉族),安徽芜湖人,硕士研究生,主要研究方向为板料成形仿真技术研究

工艺人员能够通过数值模拟技术研究、分析拉深解结构及布局对板料流动的影响,进而评定模具设计的正确性。

op

图1右前侧车门铰链加强板