您当前的位置:首页>论文资料>江海直达航道桥索塔浮吊提升转体工艺设计

内容简介

24

24DOI:10.7672/sgjs2016110024

施工技术

CONSTRUCTION TECHNOLOGY

2016年6月上第45卷第11期

江海直达航道桥索塔浮吊提升转体工艺设计

王紫超1,2,牛照1,2,陈鸣1,2

(1.中交第二航务工程局有限公司,湖北武汉430040;

2.交通部长大桥梁建设施工技术交通行业重点实验室,湖北武汉430040)

【摘要】研究了一种桥梁钢塔浮吊提升转体工艺,即由工厂拼装成整体,船运至施工现场,然后通过大型浮吊转体吊装,最后利用导向及精调位装置进行匹配。分析了转体吊装过程中可能遇到的各种问题,并对应提出了具体的、行之有效的解决措施。对转体吊耳、转动铰、滑移系统以及导向调位装置进行了深人研究,并进行了详细设计,各结构新额,可拆装性好,对钢塔损伤较小,承载能力强。最后对转体吊装及精确调位过程中钢塔的稳定性进行了系统分析,证明了整个过程安全可行。

【关键词]桥梁工程;索塔;转体;浮吊;稳定性;设计

【中图分类号]U445.465

【文献标识码]A

[文章编号]1002-8498(2016)11-0024-04

LiftingandSwivelingProcessDesignwithFloatingCraneforthe

Tower of River-sea Direct Channel Bridge

Wang Zichao'.2,Niu Zhaoi,2,Chen Ming',2

(1. CCCC Second Harbour Engineering Co. ,Lid. , Wuhan, Hubei 430040,China; 2. Key Lab of Large-spal

Bridge Construction Technology,Ministry of Communications,PRC, Wuhan, Hubei430040, China)

Abstract : This paper researches a kind of lifting and swiveling technology to the steel tower with floating crane : it was assembled in the factory, transported to the construction site by vessels, then swiveled and hoisted by a floating crane, matching using guide and refined adjustment device at last. The various kinds of problems occurring in the process are analyzed and the effectively specific solutions are proposed. The further study to swivel lifting lugs, rotating hinge, slip system, guiding and adjustable device is carried out as well as detailed design. The structure is original and removable, which is limited damage to steel tower with high bearing capacity. Finally, systematic analysis of the steel tower stability is conducted, which proves the feasibility and safety of the process.

Key words : bridges ; cable towers; swivel ; floating cranes; stability ; desigr

1工程概况

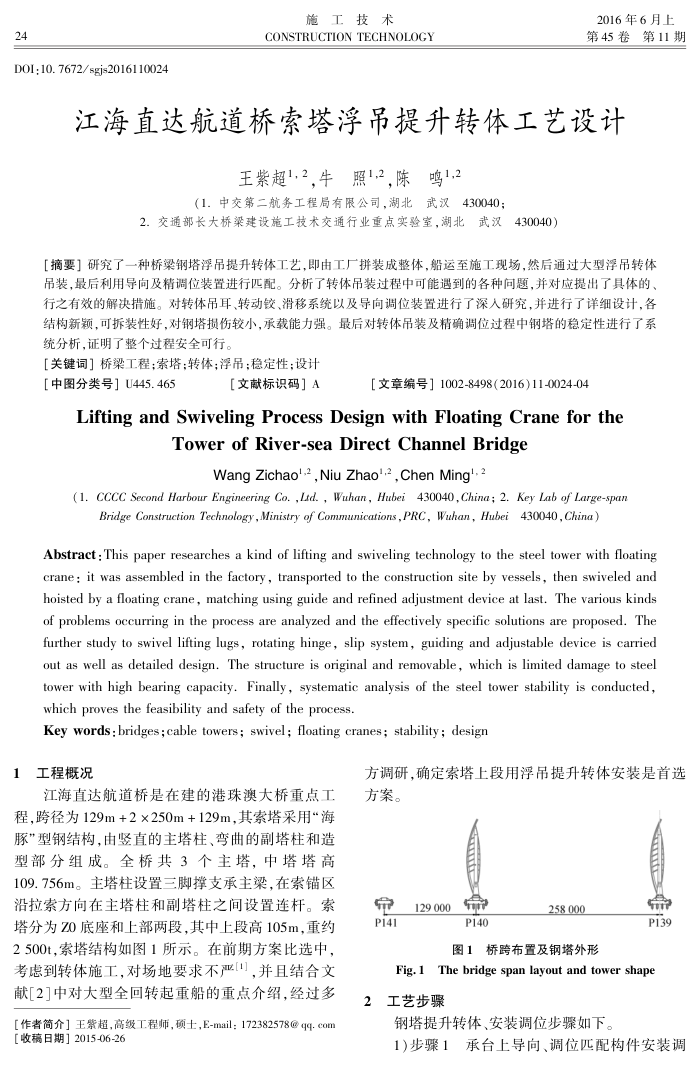

江海直达航道桥是在建的港珠澳大桥重点工程,跨径为129m+2×250m+129m,其索塔采用“海豚”型钢结构,由竖直的主塔柱、弯曲的副塔柱和造型部分组成。全桥共3个主塔,中塔塔高 109.756m。主塔柱设置三脚撑支承主梁,在索锚区沿拉索方向在主塔柱和副塔柱之间设置连杆。索塔分为Z0底座和上部两段,其中上段高105m,重约 2500t,索塔结构如图1所示。在前期方案比选中,考虑到转体施工,对场地要求不严[1],并且结合文献[2]中对大型全回转起重船的重点介绍,经过多[作者简介]王紫超,高级工程师,硕土,E-mail;172382578@qq-com【收稿日期]2015-06-26

方调研,确定索塔上段用浮吊提升转体安装是首选方案。

制 Pi41

129 000

P140

258 000

P139

图1桥跨布置及钢塔外形

Fig.1The bridge span layout and tower shape

2

工艺步骤

钢塔提升转体、安装调位步骤如下。

1)步骤1承台上导向、调位匹配构件安装调