您当前的位置:首页>论文资料>九州航道桥主塔柱垂直转体安装工艺

内容简介

2015年2月下第44卷第4期

2015年2月下第44卷第4期D0I:10.7672/sgjs2015040085

施工技术

CONSTRUCTION TECHNOLOGY

九州航道桥主塔柱垂直转体安装工艺

王紫超1,2

(1.中交第二航务工程局有限公司,湖北武汉430040;2.交通部长大桥梁建设

施工技术交通行业重点实验室,湖北武汉430040)

【摘要】对桥梁钢塔的垂直转体工艺进行详细设计,并介绍了优化设计方法;对钢塔转体过程中的受力进行分析,并对局部加固进行了说明,给出计算结果;由于转体拉力较大,不平衡力大,不可控因素较多,对转体关键设备即液压连续提升千斤顶的选型提出了技术要求:由于钢塔要转体到垂直位置,对钢塔转体过程中,尤其是对转到钢塔重

心过转点时的稳定性进行了定量分析,并提出了门架下放装置接力转体和反拉系统同时作用的解决办法。[关键词]桥梁工程;斜拉桥:钢塔:液压千斤项;安装;稳定性

【中图分类号]U448.27

【文献标识码]A

[文章编号]1002-8498(2015)04-0085-04

InstallationTechnology of the Main TowerwithVerticalSwivel Method

forJiuzhouChannelBridge

Wang Zichao'.2

(1. CCCC Second Harbour Engineering Co.,Lid. ,Wuhan,Hubei430040,China; 2. Key Lab of

Large-span Bridge Construction Technology, Ministry of Communications, PRC, Wuhan, Hubei 430040, China)

Abstract: This paper introduces optimization design method and the process of vertical swivel technology of steel tower in detail,analyzes and calculates the whole force process. The partial reinforcement to the steel tower is elaborated, then the results are provided. Because the tension is very large, and the unbalanced tension is very large too, which causes many uncontrollable factors, so this paper puts forward strict technical parameters to the key equipment for swivel, the hydraulic jack with continuous lifting Because the end position of the tower is the perpendicular finally, this paper analyzes quantitatively the stability to the whole swivel,particularly the gravity to the tower is just rotating above the shaft,and then

puts forward the methods of the relay twist with gantry lowering device and anti-pull system. Key words : bridges ; cable stayed bridges ; steel towers ; hydraulic jack ; installation ; stability

1工程概况

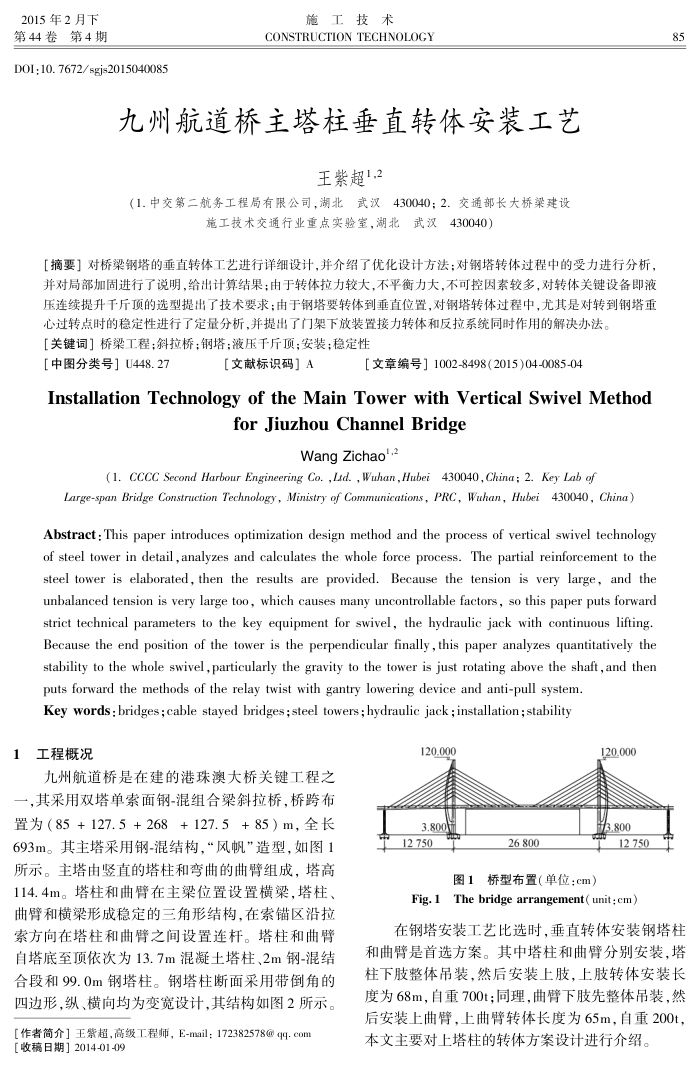

九州航道桥是在建的港珠澳大桥关键工程之一,其采用双塔单索面钢-混组合梁斜拉桥,桥跨布置为(85+127.5+268+127.5+85)m,全长 693m。其主塔采用钢-混结构,“风帆”造型,如图1 所示。主塔由竖直的塔柱和弯曲的曲臂组成,塔高 114.4m。塔柱和曲臂在主梁位置设置横梁,塔柱、曲臂和横梁形成稳定的三角形结构,在索锚区沿拉索方向在塔柱和曲臂之间设置连杆。塔柱和曲臂自塔底至顶依次为13.7m混凝土塔柱、2m钢-混结合段和99.0m钢塔柱。钢塔柱断面采用带倒角的四边形,纵、横向均为变宽设计,其结构如图2所示。

【作者简介]王紫超,高级工程师,E-mail;172382578@qq.con【收稿日期]2014-01-09

120.000 3.800% 12.750

26 800

图1桥型布置(单位:cm)

120.000 3.800

12.750

Fig.1 The bridge arrangement(unit:cm)

85

在钢塔安装工艺比选时,垂直转体安装钢塔柱和曲臂是首选方案。其中塔柱和曲臂分别安装,塔柱下肢整体吊装,然后安装上肢,上肢转体安装长度为68m,自重700t;同理,曲臂下肢先整体吊装,然后安装上曲臂,上曲臂转体长度为65m,自重200t,本文主要对上塔柱的转体方案设计进行介绍。