内容简介

塑料注射模技术

塑料注射模技术:塑料注射模技术:

皮带轮注射模设计

尹相

河源技师学院(广东河源

517000)

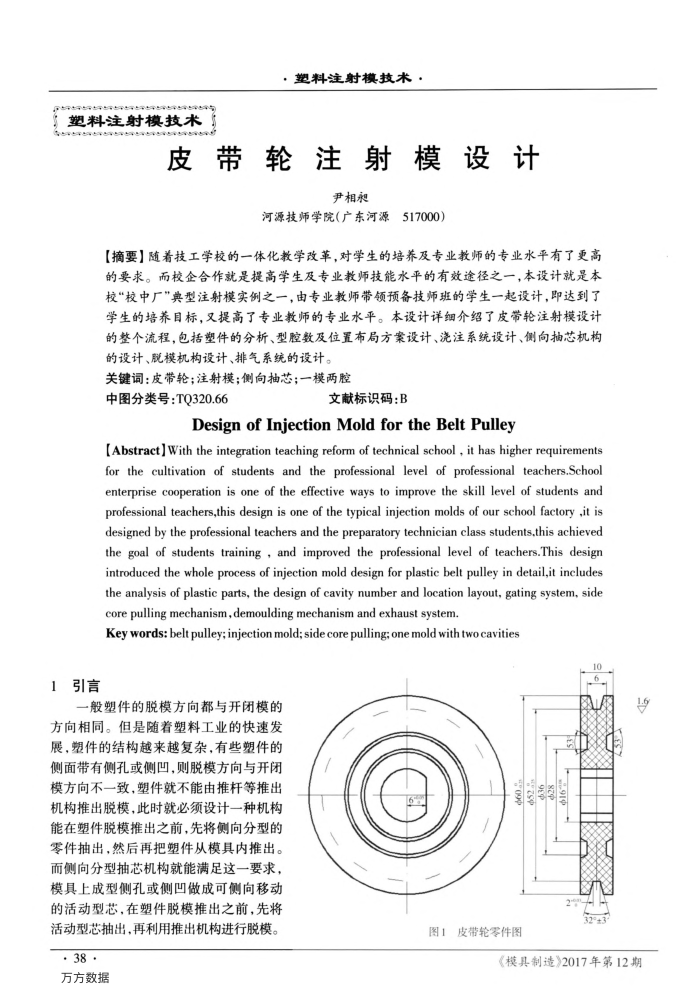

【摘要】随着技工学校的一体化教学改革,对学生的培养及专业教师的专业水平有了更高的要求。而校企合作就是提高学生及专业教师技能水平的有效途径之一,本设计就是本校“校中厂"典型注射模实例之一,由专业教师带领预备技师班的学生一起设计,即达到了学生的培养目标,又提高了专业教师的专业水平。本设计详细介绍了皮带轮注射模设计的整个流程,包括塑件的分析、型腔数及位置布局方案设计、浇注系统设计、侧向抽芯机构的设计、脱模机构设计、排气系统的设计。

关键词:皮带轮:注射模:侧向抽芯:一模两腔

中图分类号:TO320.66

文献标识码:B

DesignofInjectionMoldfortheBeltPulley

[Abstract]With the integration teaching reform of technical school , it has higher requirements for the cultivation of students and the professional level of professional teachers.School enterprise cooperation is one of the effective ways to improve the skill level of students and professional teachers,this design is one of the typical injection molds of our school factory ,it is designed by the professional teachers and the preparatory technician class students,this achieved the goal of students training , and improved the professional level of teachers.This design introduced the whole process of injection mold design for plastic belt pulley in detail,it includes the analysis of plastic parts, the design of cavity number and location layout, gating system, side core pulling mechanism,demoulding mechanism and exhaust system.

Key words: belt pulley; injection mold; side core pulling; one mold with two cavities

引言 1

般塑件的脱模方向都与开闭模的

方向相同。但是随着塑料工业的快速发展,塑件的结构越来越复杂,有些塑件的侧面带有侧孔或侧凹,则脱模方向与开闭模方向不一致,塑件就不能由推杆等推出机构推出脱模,此时就必须设计一种机构能在塑件脱模推出之前,先将侧向分型的零件抽出,然后再把塑件从模具内推出。而侧向分型抽芯机构就能满足这一要求,模具上成型侧孔或侧凹做成可侧向移动

的活动型芯,在塑件脱模推出之前,先将活动型芯抽出,再利用推出机构进行脱模。

· 38· 万方数据

图1

皮带轮零件图

20+

1

《模具制造》2017年第12期

上一章:汽车冲压模具中瞬时载荷影响的探索

下一章:加油口盖总成结构及发展方向