您当前的位置:首页>论文资料>电器支撑脚塑件注射模设计

内容简介

·塑料注射模技术·

·塑料注射模技术·电器支撑脚塑件注射模设计

刘占军

沈阳航空航天大学航空航天工程学部(辽宁沈阳110136)

【摘要】分析了支撑脚塑件的材料工艺性和结构工艺性,进行了模具方案的论证,解决了简形件成型问题。对浇注系统的主流道、冷料井、拉料杆、分流道和浇口进行了设计,还进行了脱模力的计算,对冷却系统进行了设计,给出了其特殊注射模装配结构图。实践证明:

该注射模结构合理、可靠,加工质量好,生产效率高。关键词:工艺分析;模具方案;支撑脚;注射模

中图分类号:TQ320.66

文献标识码:B

Design of Injection MoldfortheSupporting

FeetPlasticsofElectricAppliance

[Abstract] It is analyzed by the technology plastics materials and molding process of supporting feet pieces, which has carried on the mold scheme demonstration and manufacturability, the molding problem of supporting feet pieces is solved,and it is designed that the main runner, cold slug well, pull rod, the runner and gate of gating system. The ejection force is calculated, and which is design of cooling system. It is given to the assembly diagram of special injection mold. Practice has proved that the supporting feet pieces injection mold structure is reasonable, reliable , good machining quality and high production efficiency.

Key words: process analysis;mold scheme; supporting feet; injection mold

1塑件工艺分析

1.1塑件材料的工艺性分析

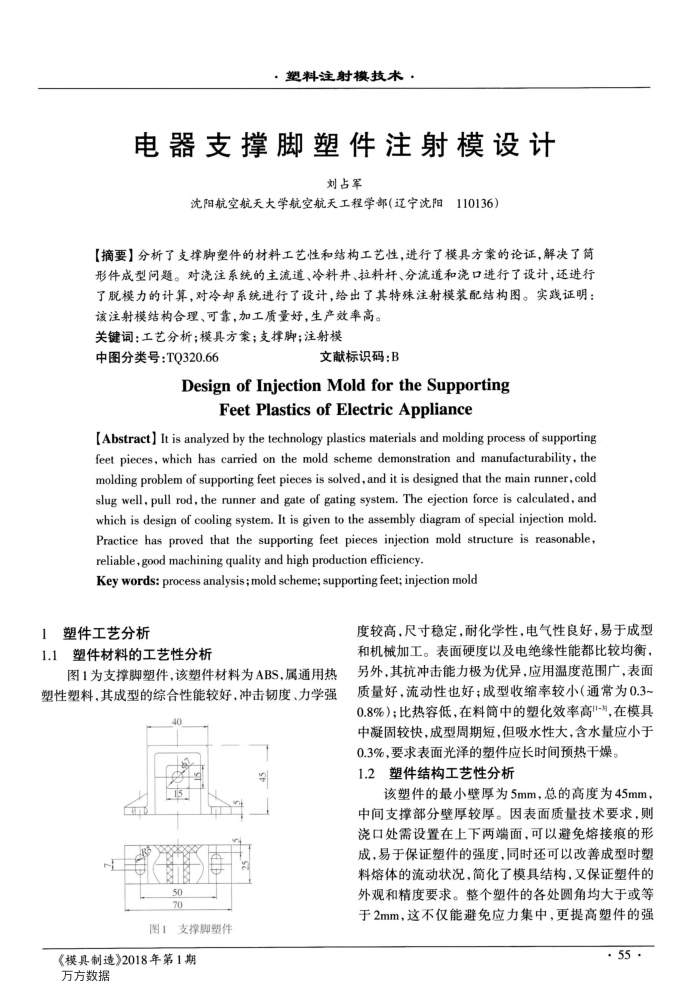

图1为支撑脚塑件,该塑件材料为ABS.属通用热塑性塑料.其成型的综合性能较好,冲击韧度、力学强

图1支撑脚塑件

《模具制造》2018年第1期万方数据

度较高,尺寸稳定,耐化学性,电气性良好,易于成型和机械加工。表面硬度以及电绝缘性能都比较均衡,另外,其抗冲击能力极为优异,应用温度范围广,表面质量好,流动性也好;成型收缩率较小(通常为0.3~ 0.8%);比热容低,在料筒中的塑化效率高-3,在模具中凝固较快,成型周期短,但吸水性大,含水量应小于

0.3%,要求表面光泽的塑件应长时间预热干燥: 1.2塑件结构工艺性分析

该塑件的最小壁厚为5mm,总的高度为45mm,中间支撑部分壁厚较厚。因表面质量技术要求,则浇口处需设置在上下两端面,可以避免熔接痕的形成,易于保证塑件的强度,同时还可以改善成型时塑料熔体的流动状况,简化了模具结构,又保证塑件的外观和精度要求。整个塑件的各处圆角均大于或等于2mm,这不仅能避免应力集中,更提高塑件的强

· 55.

上一章:电话机听筒模具型腔数控编程与加工

下一章:基于DDA直线插补的异型螺纹宏程序加工