潜孔锤在大粒径砂卵石地层大管棚施工中的改进与应用

内容简介

2015年12月上第44卷第23期

2015年12月上第44卷第23期DO1;10. 7672/sgjs2015230061

施工技术

CONSTRUCTION TECHNOLOGY

61

潜孔锤在大粒径砂卵石地层大管棚施工中的改进与应用

马敬东,廖秋林,张鹏飞,裴宝权(北京城建设计发展集团股份有限公司,北京

100088)

【摘要】大管棚超前预支护技术作为暗挖作业的辅助工法,有效为暗挖作业穿越河流、地下管线与构(建)筑物以及马头门破门提供安全保障。大粒径砂卵石地层中因其摩阻力大、采用泥浆护壁湿钻法易引起较大地层沉降等因索,长管棚施工难度大。基于北京地铁7号线达官营站管棚施工的工程实践,从施工工艺比选、试钻及工艺改进等

方面分析了大粒径砂卵石地层管棚施工的关键技术问题,并提出了改进措施与解决方案。【关键调】地铁;大管棚;暗挖;潜孔锤;施工技术

[中图分类号】U455.4

【文献标识码】A

【文章编号】1002-8498(2015)23-0061-03

ImprovementandApplicationofDTHHammerinPipeShed

ConstructioninLarge-scaleSandGravelStratum

Ma Jingdong,Liao Qiulin, Zhang Pengfei, Pei Baoquan

(Bejing Urbas Construction Design & Deselopment Group Co. ,Lad. ,Beijing 100088,China)

Abstract:Pipe shed pre-supporting technology as auxiliary method of subsurface excavation operation, provides security for subsurface excavation operation which river, underground pipeline, buildings and ingate breaking. The friction resistance is large in sand gravel stratum with large grain diameter, and the wet drilling method with mud protection is easy to cause large stratum settlement as well as other factors, which result in construction difficulty of long tube pipe shed. Based on pipe shed construction of Daguanying station of Beijing Subway Line No. 7, from the construction process selection, this paper analyzes the key construction technology of pipe shed in sand gravel stratum with large grain diamete from the aspects of construction process comparison and selection,test drilling,process improvement and so on,and puts forward improvement measures and solution.

Key words:subways;pipe shed;subsurface excavation;DTH hammer;construction

1工程概况

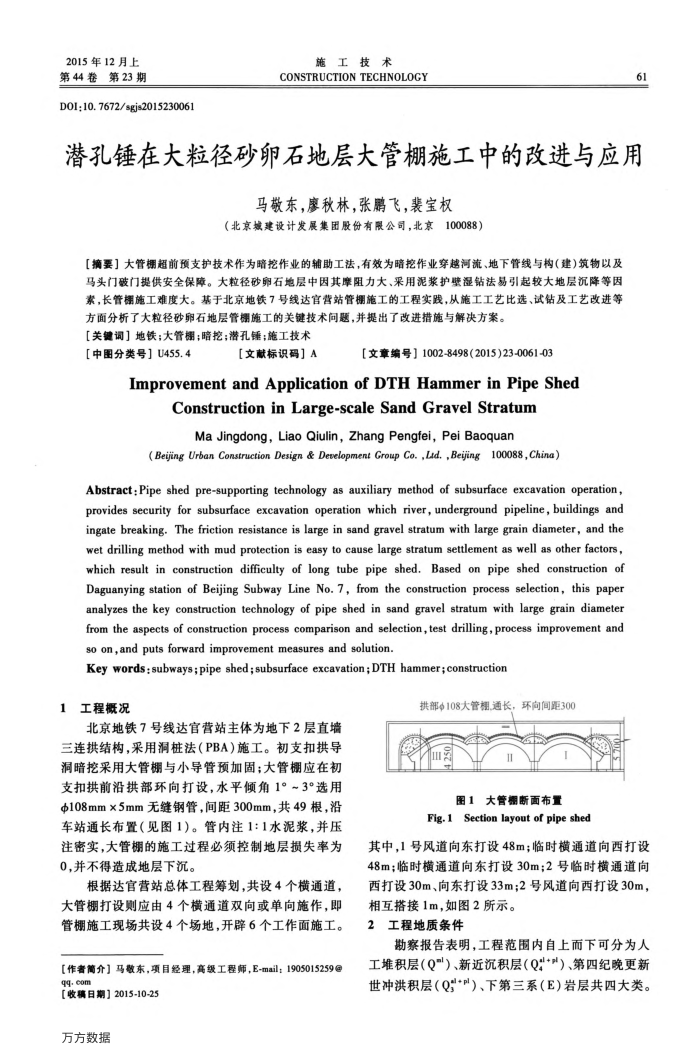

北京地铁7号线达官营站主体为地下2层直墙三连拱结构,采用洞桩法(PBA)施工。初支扣拱导洞暗挖采用大管棚与小导管预加固;大管棚应在初支扣拱前沿拱部环向打设,水平倾角1°~3°选用 Φ108mm×5mm无缝钢管,间距300mm,共49根,沿车站通长布置(见图1)。管内注1:1水泥浆,并压注密实,大管棚的施工过程必须控制地层损失率为 0,并不得造成地层下沉。

根据达官营站总体工程筹划,共设4个横通道,大管棚打设则应由4个横通道双向或单向施作,即管棚施工现场共设4个场地,开辟6个工作面施工。

【作者简介】马数东,项目经理,高级工程师,E-mail;1905015259@ qq.

【收稿日期】2015-10-25 万方数据

拱部108大管相,通长,环向间距300

图1大管棚断面布置

Fig.1 Section layout of pipe shed

其中,1号风道向东打设48m;临时横通道向西打设 48m;临时横通道向东打设30m;2号临时横通道向西打设30m、向东打设33m:2号风道向西打设30m,相互搭接1m,如图2所示。

2

工程地质条件

勘察报告表明,工程范围内自上而下可分为人

工堆积层(Q")、新近沉积层(Q:*")、第四纪晚更新世冲洪积层(Q*")、下第三系(E)岩层共四大类。