基于无线传感网络和CAN总线技术的综采面喷雾降尘系统

内容简介

2018年第37卷第10期

2018年第37卷第10期传感器与微系统(Transducer and Microsystem Technologies)

105

DOI:10.13873/J.10009787( 2018 )10010503

基于无线传感网络和CAN总线技术的综采面喷雾降尘系统

丁飞,吕自力

(辽宁工程技术大学机械工程学院,辽宁阜新123000)

摘要:目前综采工作面喷雾降尘监控系统中,多数红外传感器监测采煤机位置在环境恶劣、复杂的综采工作面中工作可靠性和实时性很难满足系统要求,因此研究一种基于控制器局域网(CAN)总线和无线传感网络(WSNs)技术的综采面喷雾降尘系统。将无线传感网络的ZigBee终端节点安装于采煤机机身,用

面CAN总线接口上传至地面数据库中。模拟实验验证了监控网络通信的可行性。关键词:无线传感网络;控制器局域网总线;ZigBee;喷雾降尘

文章编号:TD676

文献标识码:A

文章编号:1000-9787(2018)10-0105-03

sss workingfacebasedonWSNsandCANbustechnology

DING Fei, LU Zi-li

( College of Mechanical Engineering, Liaoning Technical University, Fuxin 123000, China )

oasaesoaoossseaeaee monitoring shearer position, working reliability and real-time performance is difficult to meet the requirements of the system in the harsh environment and complex fully mechanized working face. studies A spray and dust suppression system of fully mechanized mining face based on CAN bus and wireless sensor networks( WSNs ) technology. The ZigBee terminal node of WSNs is installed on the shearer body for collecting and transmitting operation state of equipment. The routing node is transmitted to the hydraulic support through WSNs, and location of the shearer can be determined in realtime according to the location algorithm. Each routing node is connected through CAN bus to ensure the high efficiency and reliability, and the data is finally uploaded to the ground database through the ground CAN bus interface. Finally, the feasibility of monitoring network communication is verified by simulation experiments.

Keywords : wireless sensor networks( WSNs ); controller area network( CAN )bus; ZigBee; spray and dust suppression

0引言

综采工作面采煤机截割煤岩时产生大量粉尘,虽然采煤机自身携带内喷雾降尘装置,但效果甚微,通常在综采工作面液压支架上安装外喷雾降尘装置弥补采煤机内喷雾降尘装置的不足(1.2)。文献[3,4]对综采工作面采煤机外喷客系统进行了深人研究和改进,提高了综采工作面采煤机外喷雾系统的喷雾降尘效率。以上研究多采用红外传感装置对采煤机运行位置进行检测,在实际综采工作面中得到广泛应用,但也存在一定的弊端。

本文设计的基于无线传感器网络(wireless sensor networks,WSNs)和控制器局域网(controllerareanetwork,收稿日期:2017-04-04

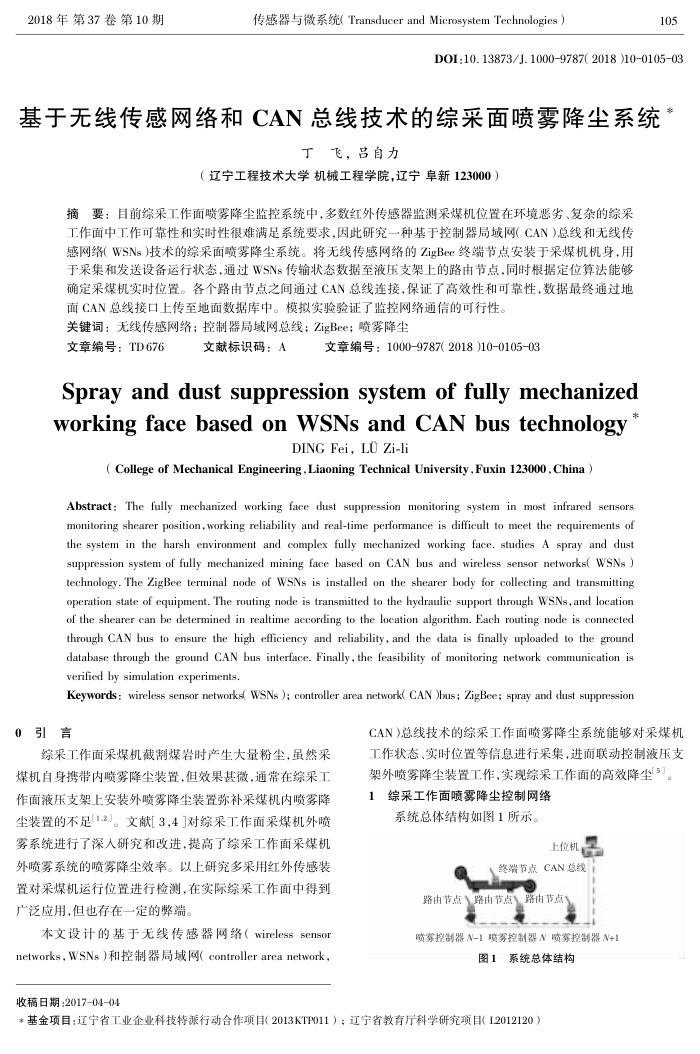

CAN)总线技术的综采工作面喷雾降尘系统能够对采煤机工作状态、实时位置等信息进行采集,进而联动控制液压支架外喷雾降尘装置工作,实现综采工作面的高效降尘5, 1综采工作面喷雾降尘控制网络

系统总体结构如图1所示。

上位机品

、终端节点CAN总线

路由节点)路由节点)、路由节点

喷雾控制器N-1喷雾控制器N喷雾控制器N+

图1系统总体结构

*基金项目:辽宁省工业企业科技特派行动合作项目(2013KTP011);辽宁省教育厅科学研究项目(I2012120)

上一章:椭圆轨道TDI CCD相机像移匹配计算与成像验证

下一章:基于双目单视面迭代算法