您当前的位置:首页>论文资料>汽车液压减振器外壳热挤压模设计

内容简介

第41卷第9期 Vol. 41No. 9

第41卷第9期 Vol. 41No. 9压技假

FORGING & STAMPING TECHNOLOGY

汽车液压减振器外壳热挤压模设计

张晓辉,陈峰伟,王笑香,蔡志刚

王少纯,

(哈尔滨工业大学机电工程学院,黑龙江哈尔滨150001)

2016年9月 Sep-2016

摘要:针对汽车减报器外壳结构特点,通过工艺分析提出通过正向挤压和侧向挤压复合工艺实现热挤压一次成形的新工艺的解决方案和设计路线,设计了减振器外壳热挤压模具。凸模头部采用平底锥形设计,可以降低单位挤压力;凹模采用挤压简和挤压回模的组合结构,可以解决凹模加工工艺性向题及使于零件的退卸料;并论述了模具的结构原理和工作原理。为确保模具符合热挤压实验的要求,对模具的关键部件进行了理论分析和计算,并通过实验方法成形出了表面光滑无缺陷、尺寸精度和力学性能均符合要求的筒形件,实验结果表明了该工艺方案和模具结构设计的可行性和实用性。

关键词:减振器外壳;热挤压工艺;一次成形;模具设计;焊缝渗漏 DOI: 10. 13330/j. issn. 1000-3940. 2016. 09, 019

中图分类号:TG376.2

文献标识码:A

文章编号:1000-3940(2016)09-0096-05

Hot extrusion die design of an automobile shock absorber shell

Wang Shaochun, Zhang Xiaohui, Chen Fengwei, Wang Xiaoxiang, Cai Zhigang(School of Electromechanical Engineering, Harbin Institute of Technology, Harbin 150001 , China)

Abstract: For the structure characteristics of the automobile shock absorber shell, the solutions and design route of the new process, which realized the hot extrusion integral forming by composite process of forward extrusion and lateral extrusion, were put forward by form ing proess analysis, and the hot extrusion die of the shock absorber shell was designed. Furthermore, the head of punch was designed as a flat botomed eone, and the unit extrusion pressure was reduxced. The die was designed as the composite structure of extnusion container and extrusion die to solve the problem of the manufacturing technology of die and the convenient withdrawal of the part. Then, the struc-ture principle and working principle of the die were discussed to ensure the die to satisfy the requirements of the hot extrusion experiment. A theoretical analysis and calculation of key components of the die were carried out. And through the experimental method, the cylindrical part is with smooth surface and without defects, its size aceuracy and mechanical properties in line with the requirements were formed out.

The experimental results show that the process scheme and the die structure design are feasible and practical. Key words: ahsorber shell ; hot extrusion process; one-step foming; die design; welding seam

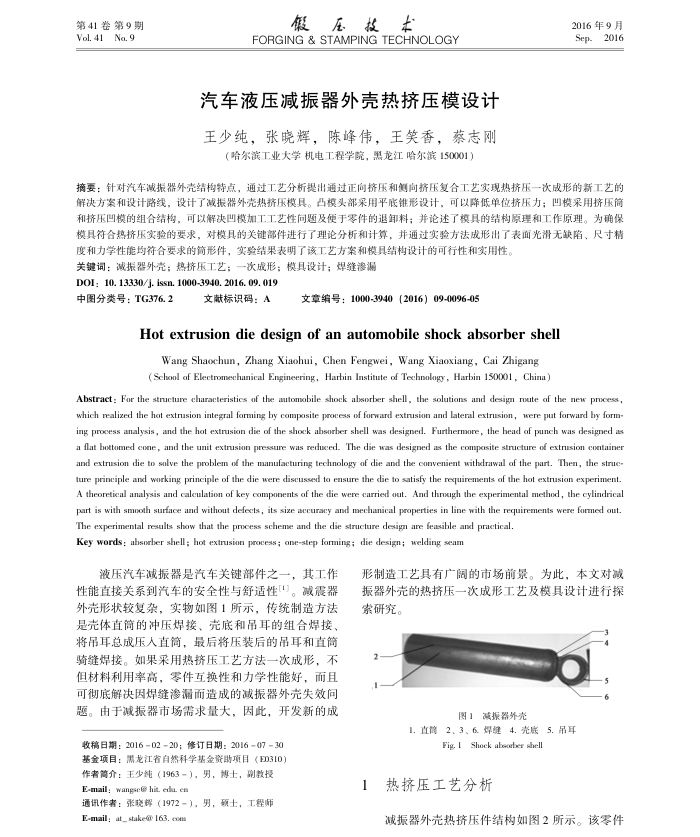

液压汽车减振器是汽车关键部件之一,其工作性能直接关系到汽车的安全性与舒适性")。减震器外壳形状较复杂,实物如图1所示,传统制造方法是壳体直筒的冲压焊接、壳底和吊耳的组合焊接、将吊耳总成压人直简,最后将压装后的吊耳和直筒骑缝焊接。如果采用热挤压工艺方法一次成形,不但材料利用率高,零件互换性和力学性能好,而且可彻底解决因焊缝渗漏而造成的减振器外壳失效问题。由于减振器市场需求量大,因此,开发新的成

收稿日期:20160220;修订日期:20160730 基金项目:黑龙江省自热科学基金资助项目(E0310)作者简介:王少纯(1963-),男,博士,副教授 E-mail: wangsc@ hit eda. en

通讯作者:张晓辉(1972-),男,额士,工程师 E-mail: at_stake@ 163. com

形制造工艺具有广阔的市场前景。为此,本文对减振器外壳的热挤压一次成形工艺及模具设计进行探索研究。

图1减振器外壳

1.直商

2、3、6.焊缝

4.壳底

5.吊耳

Fig. 1

Shock absoeber shell

1

热挤压工艺分析

减振器外壳热挤压件结构如图2所示。该零件