您当前的位置:首页>论文资料>洗衣机烘道压铸件结构工艺优化与改进

内容简介

引言 1

引言 1·压铸模技术·

洗衣机烘道压铸件结构工艺优化与改进

丁正颖",蔡东",许庭瑞',钱子龙”,陈叶娣",尤敏芳 1.江苏常州机电职业技术学院(江苏常州213164) 2.江阴美托金属制品有限公司(江苏江阴214446)

【摘要】基于已开发洗衣机烘道压铸件结构的工艺性进行分析,针对压铸件局部结构工艺提出优化思路,并结合压铸件的材质性能、装配要求、使用功能、模具开发和充填成型等方面因素,围绕压铸件的壁厚均匀、圆角过渡、斜度方向等结构工艺要求进行分析,提出具体、合理、可行的工艺改进方法。对压铸件结构工艺的优化改进,有利于提高压铸件的生

产率、合格率,同时可简化模具结构,降低模具制造成本,延长模具寿命。关键词:洗衣机烘道;壁厚均匀;工艺改进

中图分类号:TG249

文献标识码:B

OptimizationandImprovementoftheStructureProcessofthe Die-CastingParts fortheDryingRoad of theWashing Machine[Abstract] The structure of the diecasting parts manufacturability was analyzed based on the washing machine, The optimization idea of the local structure process of the diecasting parts was put forward. Considering the factors such as material properties, assembly requirements, usage functions, die-casting die development and filling molding, the structural process requirements such as uniform wall thickness, fillet transition and slope direction were analyzed. The concrete, reasonable and feasible process improvement methods were put forward. The optimization and improvement of diecasting parts structure technology can improve the productivity and qualified rate of the diecasting parts, and simplify the die structure, reduce the manufacturing cost and prolong the service life of the diecasting die.

Key words: drying road of washing machine; uniform wall thickness; improvement of process structure

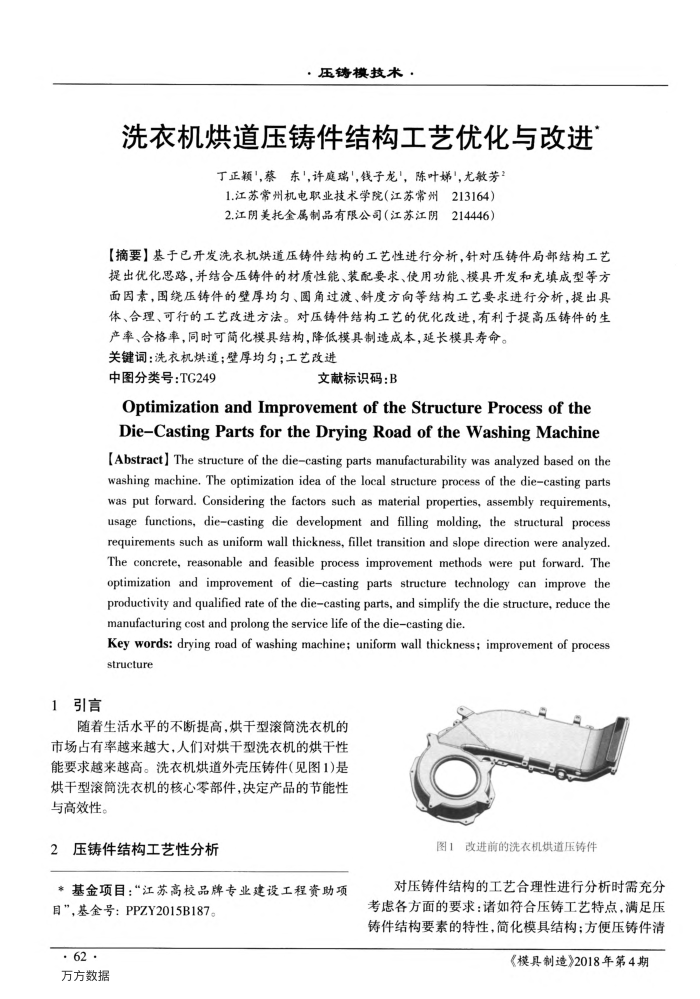

随着生活水平的不断提高,烘干型滚筒洗衣机的市场占有率越来越大,人们对烘干型洗衣机的烘干性能要求越来越高。洗衣机烘道外壳压铸件(见图1)是烘干型滚筒洗衣机的核心零部件,决定产品的节能性与高效性。

2压铸件结构工艺性分析

*基金项目:“江苏高校品牌专业建设工程资助项目”,基金号:PPZY2015B187。

· 62 · 万方数据

图1改进前的洗衣机烘道压铸件

对压铸件结构的工艺合理性进行分析时需充分考虑各方面的要求:诸如符合压铸工艺特点,满足压铸件结构要素的特性,简化模具结构方便压铸件清

《模具制造》2018年第4期