您当前的位置:首页>论文资料>循环乙烷泵轴承止推瓦磨损故障分析及处理

内容简介

ISSN1000 3762 CN41 1148/TH

ISSN1000 3762 CN41 1148/TH轴承2016年6期 Bearing 2016 , No. 6

循环乙烷泵轴承止推瓦磨损故障分析及处理

张小勤”,刘绍静

39 -42

(1.广东石油化工学院机电工程学院,广东茂名525000;2.华南师范大学物理与电信工程学院,广州

510631)

摘要:针对循环乙烷泵轴承止推瓦使用中存在的瞻损问题,对泵吸人不良、轴承润滑不良、轴承振动进行了分析,并对泵进行力学分析计算,结果表明:叶轮背面的平衡孔过小,不能有效地平衡轴向力是造成轴承止推瓦严重瞻损的主要原因,提出了采用加大平衡孔直径的措施来提高其平衡能力,大大延长了泵的使用寿命,保证了装置的平稳运行,

关键词:滑动轴承:循环乙烷泵;止推瓦:磨损:处理措施

中图分类号:TH133.31;0313.5

文献标志码:B

文章编号:10003762(2016)06003904

AnalysisandCounterMeasuresforWearFaultofThrustTileforBearings

Used in Circulating Ethane Pump

Zhang Xiaoqin', Liu Shaojing

( 1. College of Machinical and Electronical Engineering, Guangdong University of Petrochemical Technology , Maoming

525000, China;2. School of Physics and Telecommunication Engineering, South China Normal University,

Guangzhou 510631,China)

Abstract: Aiming at wear of thrust tile for bearings used in circulating ethane pump, the poor suction of pump, poor lubrication and vibration of bearings are analyzed. The mechanical analysis and calculation are carried out for pump. The results show that the balance hole on backside impeller is too small to effectively balance the axial force, which is the main reason for severe wear of thrust tile for bearings. It is proposed that the balance ability is improved by increas-ing diameter of balance hole . The service life of pump is greatly extended, and the smooth running of device is guaran teed.

Key words: sliding bearing; cireulating ethane pump; thrust tile; wear; treatment measure

1

概述

P-470A/S循环乙烷泵是将裂解炉出来的副产品乙烷返回裂解炉再裂解成乙烯的关键设备。2 台泵(一开一备)经常发生摆动大、运转不稳定、由于外部因素导致前轴承磨损严重等问题,频繁停车检修不仅大大增加维护成本,且影响乙烷的回收,造成巨大的经济损失,因此,有必要分析其磨损故

障的根本原因,采取有效措施,确保正常生产。收稿日期:20160126;修回日期:20160303

作者简介:张小勤(1968一),女,汉族,实验师,本科,主要从事机电工程、化工机械设备等教学与试验工作,E-mail: zxq2923365@ 163, com

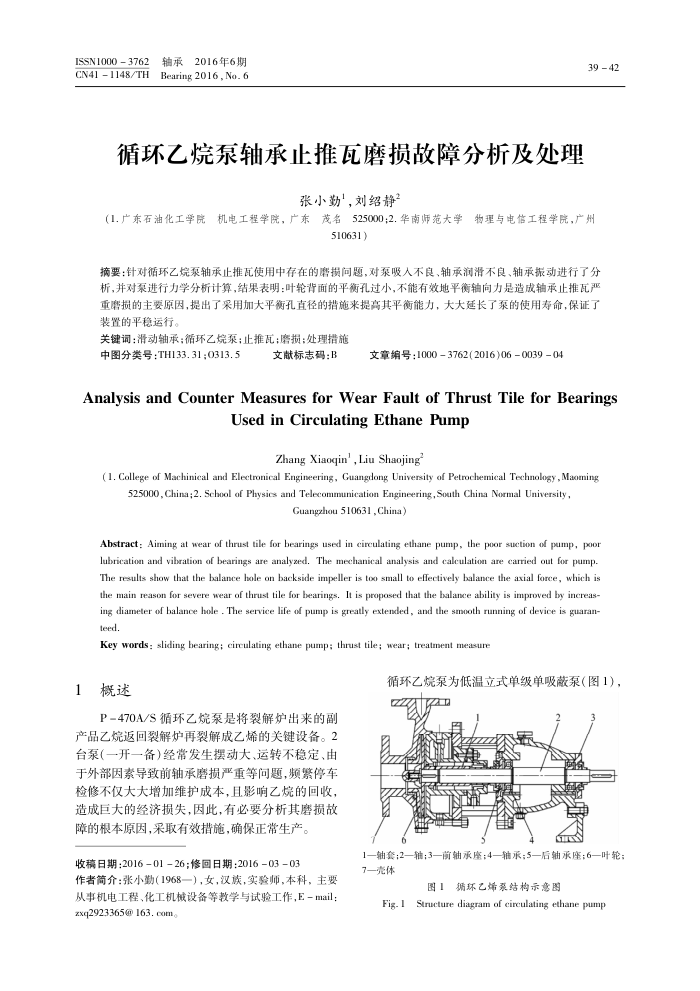

循环乙烷泵为低温立式单级单吸蔽泵(图1), 1—轴套;2—轴;3—菌轴承座;4—轴承;5—后轴承座;6—叶轮; 7—壳体

图!插环乙烯系结构示意图

Structure diagram of circulating ethane pump

Fig-1