利用罐式煅烧炉烟气进行余热发电的可行性研究

内容简介

36

36应用能源技术

2010年第1期(总第145期)

利用罐式烧炉烟气进行余热发电的可行性研究

李秀莉

(湖南永清环保研究设计院,湖南长沙410005)

摘要:我国石油焦焕烧以罐式焕烧炉和回转窑为主。罐式焕烧炉是我国最早采用的一种焕烧设备,能够焕烧不同挥发份含量的生石油焦,具有锻烧料质量稳定,炭质烧损率低,焕后焦的堆积密度高,操作简单、维护工作量小、连续生产的周期长等优点,固此广泛应用于大、中小炭素厂和铝用炭素行业中。罐式炉焕烧过程产生大量烟气,风温很高,通常高达950℃以上,供导热油炉的部分用热后烟气也有600℃。烟气热烩高,可利用其来生产蒸汽进行发电,既能有效提高企业自供电率,实现企业节能减排降耗增效,可取得良好的社会效益、经济效益和环境效益。本文介绍了罐式焕烧炉烟气余热利用发电的可行性。

关键词:罐式焕烧炉烟气;余热发电;节能降耗;经济效益;社会效益

中图分类号:TK227.1文献标识码:B文章编号:1009-3230(2010)01-003604 FeasibilityStudyofUsingWasteHeattoGenerateElectric PowerwhichComesfromtheGasofPot-typeCalciner

LI Xiu -li

(Hunan Yongqing Environmentprotection Study institute, Changsha 410005,Hunan)

Abstract: The main buming methods of petroleum coke in our county are pottype calciner and rotary kiln. Pot - type calciner is the earliest buming equipment used in our country which can bum raw petroleum coke with different volatile content, Its advantages include stable quality of buming material, low buming waste of carbon, high coke piling density afier buming, easy operation, low maintenance and long period of continuous production, so the pot type calciner is used widely in the carbon factory of middle and big sizes and aluminum carbon industry. Much gas is produced during the buming of pot type calciner, the gas temperature is usually over 950°C and it could be 600℃ even afer using by heat conducting oil boiler. The high enthalpy of gas can be used to produce steam to generate electric power, which could increase the electricity supply for the company itself to realize energy saving and waste -reducing, better social, economic and environmental benefits could be gained. This paper introduces the Feasibility of using Waste heat to generate electric power which comes from the gas of pot type calciner. Key words: Pot type calciner gas; Using Waste Heat to generate electric power; Energy saving and wastereducing;Economic benefits;Social benefits

1罐式炉烟气余热计算 1.1罐式炉缎烧烟气量

以一个年产20万吨的罐式炉石油焦生产厂收稿日期:2009-12-10

修订稿日期:2009-12-30

作者简介:李秀莉,女,1992年毕业于西南科技大学,从事余

热电工程设计。

万方数据

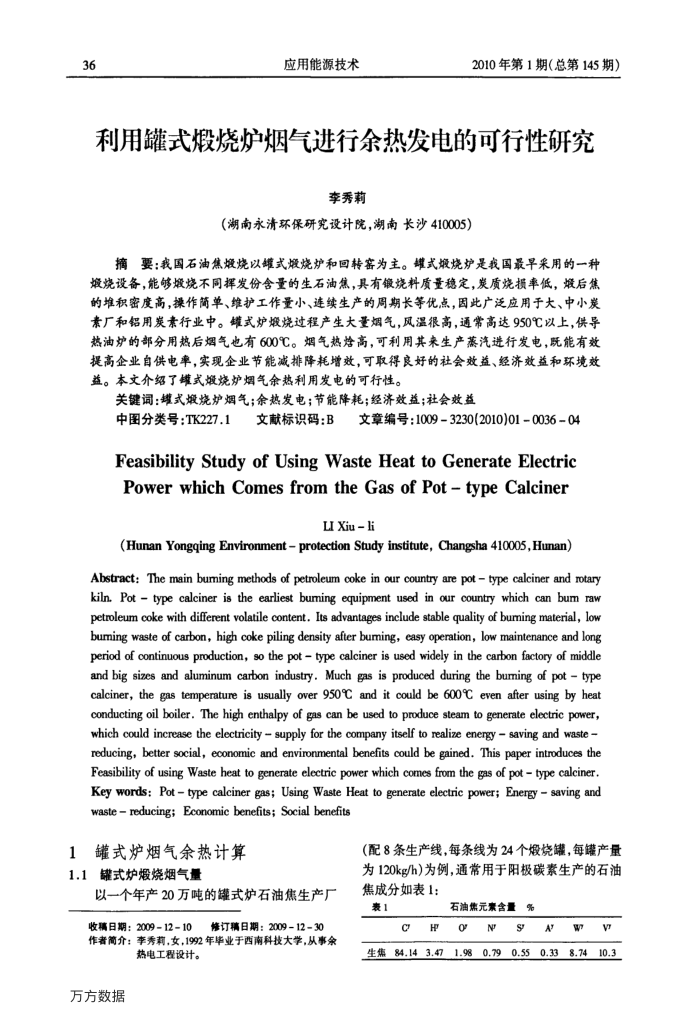

(配8条生产线,每条线为24个缎烧罐,每罐产量为120kg/h)为例,通常用于阳极碳素生产的石油焦成分如表1:

表1

C

生焦84.14

H 3.47

石油焦元素含量

0 1.98

N 0.79

s 0.55

A 0.33

W 8.74

A 10.3

上一章:某330MW燃煤发电机组节能诊断的研究与探讨

下一章:论电网线路安全运行管理