您当前的位置:首页>论文资料>仪表塑件结构缺陷工艺分析及解决办法

内容简介

塑料注射模技术

塑料注射模技术塑料注射模技术:

仪表塑件结构缺陷工艺分析及解决办法

林鸣德

厦门南洋职业学院(福建厦门361101)

【摘要】介绍了解决塑件质量问题的一种方法,首先对实物和现场进行分析、对比,对塑件结构、模具进行局部改进。经生产验证,更改后的塑件结构、模具结构合理,塑件存在的质量问题得到彻底解决。塑件质量得到了提升,提高了生产效率,降低了生产成本,也延长

了模具的寿命,使模具能够继续发挥作用,取得了良好的经济效益。关键词:结构设计;模具设计;毛刺;飞边;注射压力

中图分类号:TQ320.66

文献标识码:B

TechnicalAnalysisandSolutionsforStructural

DefectofInstrumentParts

[Abstract] This paper introduces a method to solve the problem of product quality: we first analyze and compare the subjects and environment, then make local improvements of the parts structure and molds, last we do a production test, the product structures and mold structures remain reasonable after modification. Which not only solves product quality problems, enhance the quality of products, improves production efficiency, reduce the production cost, but also improve the service life of the mold to continue to work and thus achieves good economic benefits in production.

Key words: structural design; mold design; burr; flying edge; injection pressure

问题的提出

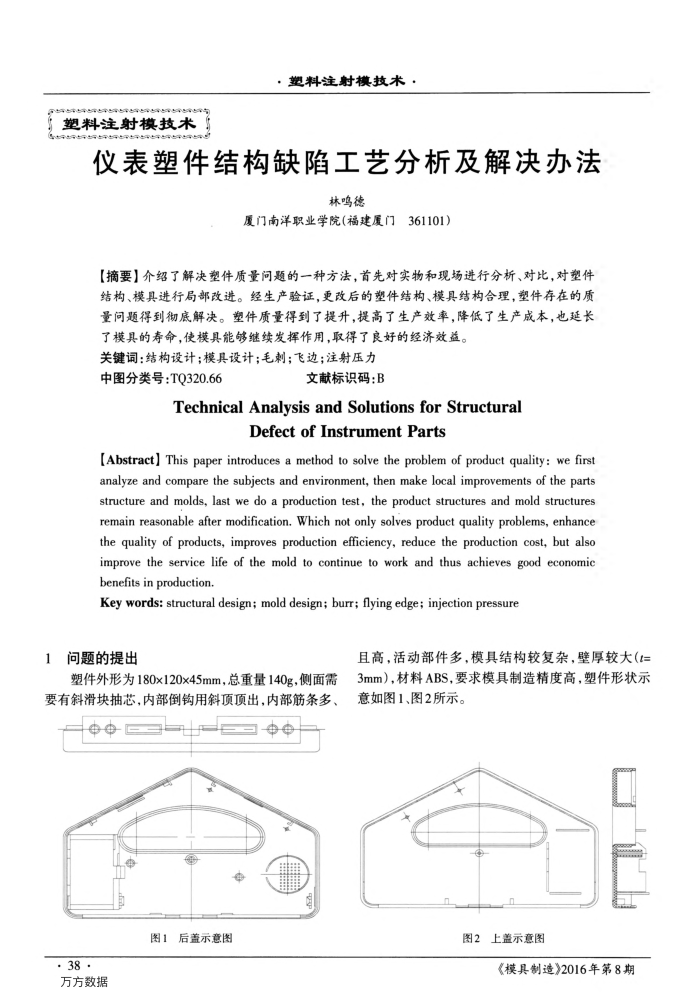

塑件外形为180x120x45mm,总重量140g,侧面需要有斜滑块抽芯,内部倒钩用斜顶顶出,内部筋条多、

05

·38· 万方数据

后盖示意图图1

o

且高,活动部件多.模具结构较复杂,壁厚较大(t 3mm),材料ABS,要求模具制造精度高,塑件形状示意如图1、图2所示。

图2上盖示意图

《模具制造》2016年第8期

上一章:项目教学在冲压模制造课程中的应用

下一章:深锥形件成形工艺及模具设计