您当前的位置:首页>论文资料>反光灯罩注塑模具设计

内容简介

模具技术2017.No.6

模具技术2017.No.6文章编号:1001-4934(2017)06-0007-03

反光灯罩注塑模具设计

任天娟

(陕西国防工业职业技术学院数控工程学院,陕西西安710300)

7

摘要:根据对反光灯军塑件的工艺分析,确定采用一模二腔的模具结构。选用潜伏式浇口,浇口位置设置在塑件的侧面。采用的抽芯机构为液压抽芯。在动、定模镶块分别设置了冷却循环水路。推出机构为推杆推出,并且设计了先复位机构。整套模具

结构合理,生产精度高,注塑的产品外观美观、表面光滑。关键词:注塑模具;反光灯罩;侧抽芯

中图分类号:TG241

文献标识码:B

The injection mould design of luminaire bracket

REN Tian-juan

Abstract: According to the process analysis of plastic luminaire bracket, the mould structure of one die and two cavities was determined. The submarine gate was chosen, and the position of the gate was set on the side surface of the plastic. The hydraulic pressure core-drawing mechanism was cho-sen,the cooling circulation waterway was set in moving die insert and fixed die insert. The ejecting mechanism is push rod pushout,and antecedence reposition mechanism was designed.The whole set of mould has reasonable structure and high precision. The product made by this kind of mould has beautiful extcrior appcarance and smooth surface.

Keywords: injection mould; luminaire bracket; side core-pulling

压抽芯机构;推出机构采用推杆推出。

塑件工艺分析和模具设计方案 1

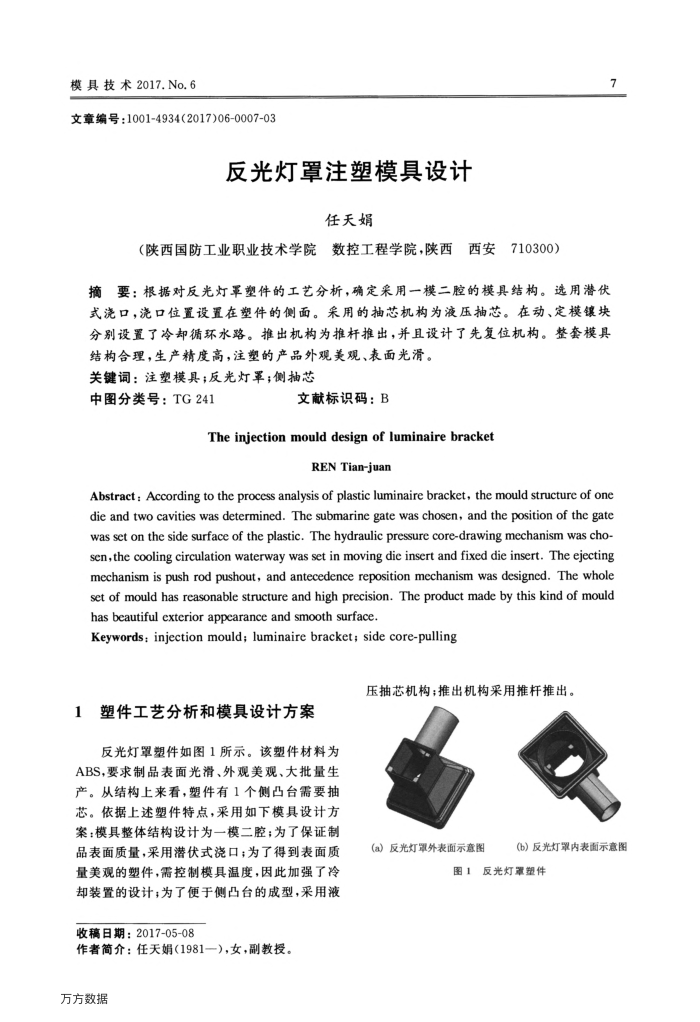

反光灯罩塑件如图1所示。该塑件材料为 ABS,要求制品表面光滑、外观美观、大批量生产。从结构上来看,塑件有1个侧凸台需要抽芯。依据上述塑件特点,采用如下模具设计方案:模具整体结构设计为一模二腔;为了保证制

品表面质量,采用潜伏式浇口;为了得到表面质量美观的塑件,需控制模具温度,因此加强了冷却装置的设计;为了便于侧凸台的成型,采用液

收稿日期:2017-05-08

作者简介:任天娟(1981一),女,副教授。万方数据

(a)反光灯罩外表面示意图

(b)反光灯罩内表面示意图

图1反光灯罩塑件

上一章:PVC管件自动切断浇口注塑模具设计

下一章:基于UG的摩托车后尾盖模具设计及制造