350MW汽轮机高调阀拉杆断裂原因分析及修复

内容简介

30

30东北电力技术

NORTHEASTELECTRICPOWERTECHNOLOGY

2014年第7期

350MW汽轮机高调阀拉杆断裂原因分析及修复

李岩,苏蔚

(阜新发电有限责任公司,辽宁阜新123003)

摘要:通过对350MW汽轮机组高调阅拉杆断裂情况分析,拉杆断裂原因是局部应力过大引起疲劳断裂。对拉杆结构进行分析和改进,降低拉杆的应力集中。对拉杆和油动机执行机构关系进行分析,得出油动机油缸的活塞杆行程设计误差值大于对应阀位设计误差值,使拉杆载荷增加,加大拉杆的应力。调整高调阀阀位请求信号略大于实际阀位,保

证拉杆不过载,同时对拉杆进行现场临时修复。关键词:拉杆;断裂;改进;修复

【中图分类号]】TK269[文献标志码]A【文章编号]】1004-7913(2014)07-0030-03

CauseAnalysis andRepairof High-profileValveSpringRodFracture

for350MWSteamTurbineUnit

LI Yan, SU Wei

(Fuxin Power Generation Co. , Ld. , Fuxin, Liaoning 123003, China)

Abstract: Based on 350 MW steam turbine unit of high-profile valve rod fracture cause analysis, tie rod fracture is due to local stress caused by fatigue fracture, The rod structure is analyzed and improved, and the stress concentration of the tie rod is reduce, Actuator motivations of rod and oil are analyzed, the relationship between the actuator rod and the oil motive is analyzed, it comes out that pis-ton stroke design error value is greater than the corresponding oil motive cylinder valve design eror value, The pull rod load is in-creased, so is the stress of the tie rod. High-profile valve adjustment request is slightly larger than the actual valve position signal to

ensure that rod set.Site temporary repair of rod can be done at the same time Key words: Tie rod; Fracture; Improvement; Repair

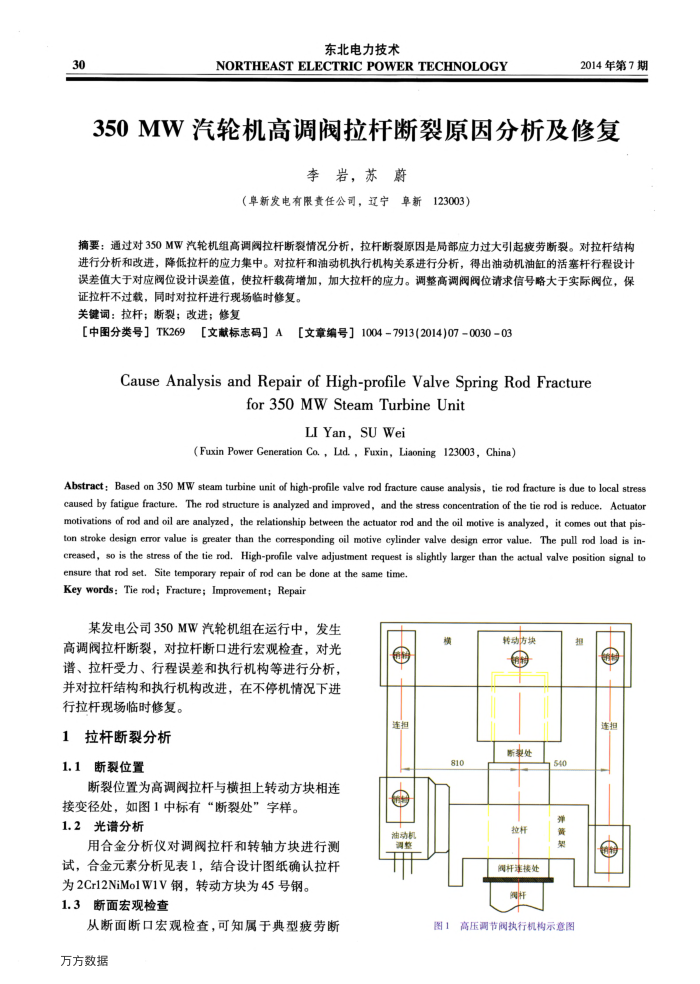

某发电公司350MW汽轮机组在运行中,发生高调阀拉杆断裂,对拉杆断口进行宏观检查,对光谱、拉杆受力、行程误差和执行机构等进行分析,并对拉杆结构和执行机构改进,在不停机情况下进

行拉杆现场临时修复。 1拉杆断裂分析 1.1断裂位置

断裂位置为高调阀拉杆与横担上转动方块相连

接变径处,如图1中标有“断裂处”字样。 1.2光谱分析

用合金分析仪对调阀拉杆和转轴方块进行测试,合金元素分析见表1,结合设计图纸确认拉杆

为2Cr12NiMo1W1V钢,转动方块为45号钢。 1.3断面宏观检查

从断面断口宏观检查,可知属于典型疲劳断万方数据

由动

模 810

转动方块

连推

断黎处

弹

拉杆

阅杆津接处阀杆

图1高压调节阀执行机构示意图