您当前的位置:首页>论文资料>旋转压缩机吸油管特性数值研究

内容简介

设计研究

设计研究文章编号:10062971(2012)05-001004

旋转压缩机吸油管特性数值研究王刚,张杰,吴建华

(西安交通大学能源与动力工程学院,陕西西安710049)

摘要:在不考虑润滑油可压编性的条件下,采用标准k-漓流模型,对旋转压缩机供油系统进行了数值模拟,分析了吸油管入口大小对供油量的影响,并揭示了吸油管内压力分市及影响供油量的机理。计算结果表明:当吸油管入口太小时,由于节流效应,供油系统供油量明显不足;当吸油管入口太大时,虽然节流效应已不明显,但是吸油管内壁面无法形成高压区,供油量反而减小。吸油管入口大小存在一个最优值,此时节流效应不明显,又能在吸油管内壁面形成高压区,从而使供油系统达到最大供油量。

关键词:旋转压编机;吸油管;数值模拟

中图分类号:TH455

文献标志码:A

Numerical Study on the Characteristic of the Oil Suction Pipe for aRotary Compressor WANG Gang,ZHANG Jie, WU Jian-hua

(School of Energy and Power Engineering,Xi'an Jiaotong University,Xian 710049, China)

Abstract: Without consideration of the compressibility of the lubricating oil,the oil supply system of a rotary compressor was numeri-cally simulated.The standard k-g turbulence model was employed in the simulation. Furthermore,the effect of the size of the oil su-ction pipe's inlet on the oil flow rates was analyzed,and the pressure distribution in the oil suction pipe and the mechanism of the effect on the oil flow rates were revealed.The simulation results indicate that the lubricating oil is insufficient due to the throttling effect when the size of the oil suction pipe's inlet is too small. When the size of the oil suction pipe's inlet is too large,the high pressure cannot be generated on the interior wall of the oil suction pipe though the throttling effect is not obvious,leading to the insufficient

lubricating oil.Hence there exists an optimal value of the oil suction pipe's inlet which could generate a maximum oil delivery. Keywords : rotary compresor; oil suction pipe; numerical simulation

引信

在旋转压缩机中,供油系统对其轴承及整机的可靠性影响很大,是确定其是否能正常运转和耐久性的重要因素之一。适当的润滑油量有利于轴承形成一定厚度的油膜,降低摩擦损失,减少摩擦热与磨损量,带走了摩擦产生的热量和磨屑。润滑油供给不足会导致润滑油平均温度与轴承工作温度大幅度提高,润滑油粘度下降,摩擦损失和曲轴与轴承磨损量增大,压缩机的性能与可靠性下降。

旋转压缩机供油系统结构复杂,内部结构参数对供油量有很大的影响。但是大部分结构参数已经由压缩机的工况确定,不能随意改变。安装

收稿日期:201204-06 10m质机技术

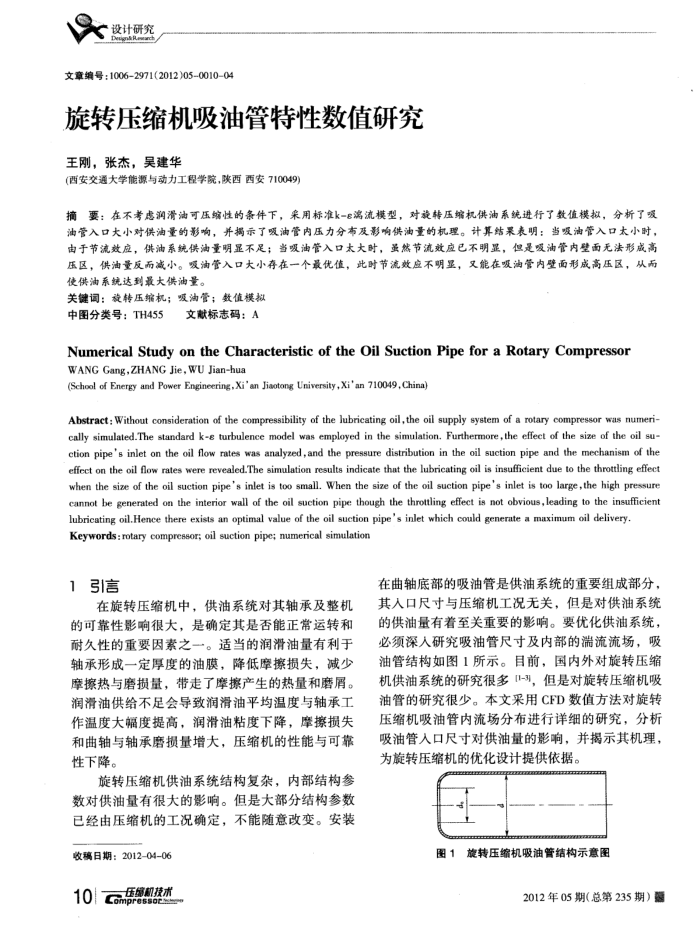

在曲轴底部的吸油管是供油系统的重要组成部分,其入口尺寸与压缩机工况无关,但是对供油系统的供油量有着至关重要的影响。要优化供油系统,必须深人研究吸油管尺寸及内部的湍流流场,吸油管结构如图1所示。目前,国内外对旋转压缩机供油系统的研究很多(I-3),但是对旋转压缩机吸油管的研究很少。本文采用CFD数值方法对旋转压缩机吸油管内流场分布进行详细的研究,分析吸油管人口尺寸对供油量的影响,并揭示其机理,为旋转压缩机的优化设计提供依据。

旋转压缩机吸油管结构示意图

图1

2012年05期(总第235期)题

上一章:压缩机节能的标准探讨

下一章:无升程限制器舌簧阀在微型无油压缩机上的应用