您当前的位置:首页>论文资料>汽车内饰配件多工位级进模设计

内容简介

第42卷第9期 Vol. 42No. 9

第42卷第9期 Vol. 42No. 9假压技木

FORGING & STAMPING TECHNOLOGY

汽车内饰配件多工位级进模设计

徐超辉,韩翠红

(天津职业技术师范大学汽车模具智能制造技术国家地方联合工程实验室,天津300222)

2017年9月 Sep.2017

摘要:介绍了一款汽车内饰配件的多工位级进模设计。通过Dynaform板料分析软件对产品的冲压成形过程进行数值模拟分析准确预测出该零件的成形缺陷。根据零件不同位置和角度的弯曲成形特征,本设计增设了两次成形申间过程,利用多次弯曲的方法,将各冲压成形区域在冲压方向上完全开放,使其不发生干涉,最终确定了包含冲裁、弯曲等工艺的11工位排样设计。通过企业生产验证,所设计的多工位级进模结构紧凌合理,产品成形质量稳定,生产效率高,可以满足大批量生产的需要。

关键词:汽车内饰配件;多工位级进模;排样设计;Dynafom;冲压成形 DOI: 10. 13330/j. issn. 1000-3940. 2017. 09, 025

中图分类号:TG386

文献标识码:A

文章编号:1000-3940(2017)09-0135-05

Designonmulti-positionprogressivedie for autointeriorparts

Xu Chaohui', Han Cuihong

( Nation Local Joint Engineering Laboratory of Intelligent Manufacturing Oriented Automobile Die & Mould, Tianjin

University of Technology and Education, Tianjin 300222, China)

Abstract : It is introduced the multi position progressive die design of auto interior parts. Then, the stamping forming process of part was mumerically simulated by software Dynaform, and the defects of part were predicted accurately- According to the bending characteristices of parts at diferent positions and angles, two bending middle processes were added, and the 11 position layout design including blanking and bending were finally determined by multi bending to make all stamping areas unrestricted in stamping directions so as to avoid inter-ference. The actual production proves that the multi position progressive die is compact and reasonable, and the quality of parts is stable with high efficiency to meet the needs of mass production.

Key words : auto interior parts; multi position progressive die; layout design; Dynafom; stamping forming

当今制造业水平迅猛发展,汽车的制造成本、

研发制造周期不断降低和缩短,汽车的品质不断提升,汽车已经越来越多地被大众消费者所接受,成为了生活必需品,良性循环也给汽车工业及相关产业带来极大的商机。因此,如何提升现有汽车零配件产品的生产效率已经成为每个从业人员考虑的核心问题[2]。

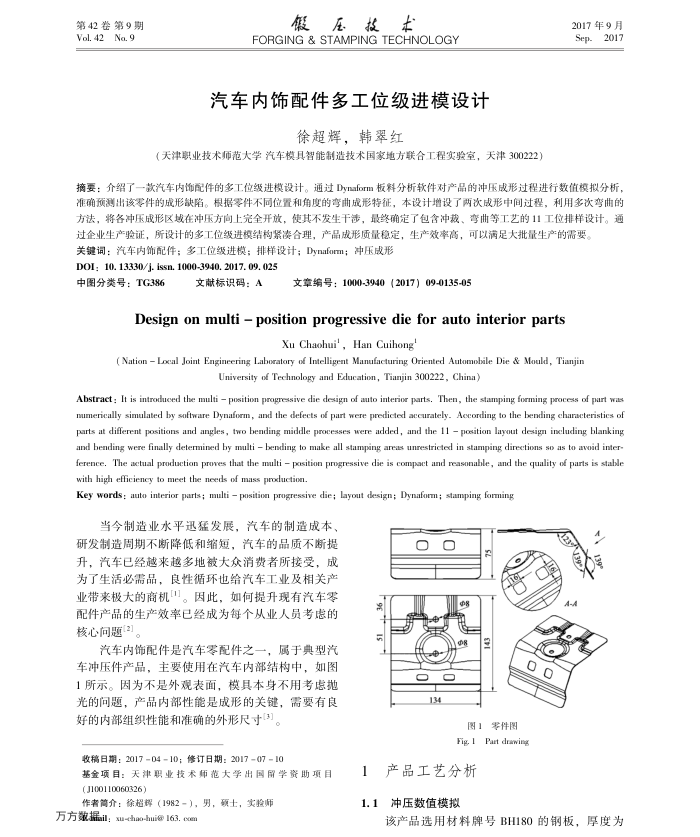

汽车内饰配件是汽车零配件之一,属于典型汽车冲压件产品,主要使用在汽车内部结构中,如图 1所示。因为不是外观表面,模具本身不用考虑抛光的问题,产品内部性能是成形的关键,需要有良

好的内部组织性能和准确的外形尺寸[3] 收稿日期:20170410;修订日期:20170710

基金项目:天津职业技术师范大学出国留学资助项目(J100110060326)

作者简介:徐超辉(1982-),男,额士,实验师万方数据il;xu-chao-hui@163.oxm

1

0

0

134

图1零件图 Fig. 1

Part drawing

产品工艺分析

1.1

冲压数值模拟

该产品选用材料牌号BH180的钢板,厚度为

上一章:镁合金热连轧过程数值模拟

下一章:换辊小车横移车架结构的多目标优化设计