您当前的位置:首页>论文资料>三种渗碳淬火钢对内氧化敏感性研究

内容简介

NN

NN~试验研究~

NNNNNN

三种渗碳淬火钢对内氧化敏感性研究

张尔康,张忠和,王全振,王飞宇,于广义,王思倩

(沈阳鼓风机集团股份有限公司,辽宁沈阳110869)

摘要:对17CrNiMo6、18CrNiMo7-6和12Cr2Ni4三种钢在不同渗碳、泽火工艺过程中产生内氧化的敏感性

进行了试验研究。采用金相法评定了内氧化的级别。结果表明,三种钢的抗内氧化性能由好到差的顺序为17CrNiMo6钢、12Cr2Ni4钢和18CrNiMo7-6钢;这些钢采用调质作为预备热处理比采用正火、回火作为预备热处理的抗内氧化性能好。此外,17CrNiMo6钢和18CrNiMo7-6钢是渗碳后二次淬火的抗内氧化性能好,而12Cr2Ni4钢是渗碳后一次率火的抗内氧化性能好。

关键词:内氧化;渗碳;萍火

中图分类号:TG156.8;TG115.5;TG115.21

文献标识码:A

文章编号:1008-1890(2017)04-0036-04

Research on Susceptibility of ThreeKinds of Steel toInner Oxidation

During Carburizing and Hardening

ZHANG Erkang,ZHANG Zhonghe,WANG Quanzhen,WANG Feiyu,

YU Guangyi, WANG Siqian

(Shenyang Blower Works Group Co., Ltd., Shenyang 110869, Liaoning China)

Abstract: It has been experimentally investigated whether three kinds of steel such as 17CrNiMo6, 18CrNiMo7-6, and 12Cr2Ni4 steels are easy to produce inner oxidation in the course of different carburizing and then hardening processes. The grades of the inner oxidation were evaluated by a metallographic examination. The results show that so far as the resistance to inner oxidation concerned, 17CrNiMo6 steel is the best, and 18CrNiMo7-6 steel is the worst of the three steels, and that the three steels previously hardened and high tempered were less susceptive to inner oxidation than ones previously normalized and tempered. In addition, both the 17CrNiMo6 and 18CrNiMo7-6 steels exhibited better resistance to inner oxidation during carburizing and double quenching, whereas the 12Cr2Ni4

steel exhibited better resistance to inner oxidation during carburizing and single quenching. Key words: inner oxidation; carburizing: quenching

试验材料及方法

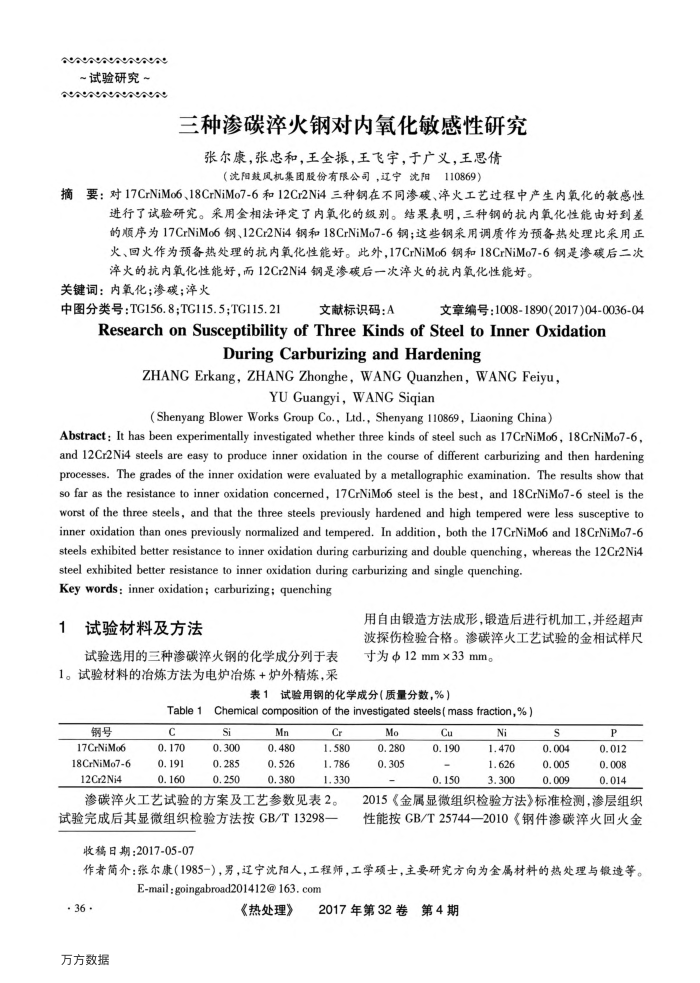

试验选用的三种渗碳淬火钢的化学成分列于表 1。试验材料的冶炼方法为电炉冶炼+炉外精炼,采

用自由锻造方法成形,锻造后进行机加工,并经超声波探伤检验合格。渗碳淬火工艺试验的金相试样尺寸为Φ12mm×33mm。

表1试验用钢的化学成分(质量分数,%)

Table1

钢号 17CrNiMo6 18CrNiMo7-6 12Cr2Ni4

c 0.170 0.191 0.160

Chemical composition of the investigated steels(mass fraction,%)

Mn 0.480

0.300

0.285 0.250

0.526 0.380

Cr 1.580 1.786 1.330

渗碳淬火工艺试验的方案及工艺参数见表2。试验完成后其显微组织检验方法按GB/T13298一

收稿日期:2017-05-07

Mo 0.280 0.305

Cu 0.190-0.150

Ni 1.470 1.626 3.300

S 0.004 0.005 0.009

P 0.012 0.008 0.014

2015《金属显微组织检验方法》标准检测,渗层组织性能按GB/T25744—2010《钢件渗碳淬火回火金

作者简介:张尔康(1985-),男,辽宁沈阳人,工程师,工学硕士,主要研究方向为金属材料的热处理与锻造等。

E-mail:goingabroad201412@163.com

· 36· 万方数据

《热处理》

2017年第32卷

第4期

上一章:单排喷嘴喷射淬火过程的温度场模拟分析

下一章:受电弓拉杆断裂失效分析