您当前的位置:首页>论文资料>小方坯连铸机结晶器振动液压系统优化

内容简介

机械工程师

机械工程师MECHANICAL ENGINEER

小方坏连铸机结晶器振动液压系统优化

王曲业,涂晨,张小勇

(1.江苏沙钢集团有限公司,江苏张家港215625;2.韶关液压件厂有限公司,广东韶关512027)

摘要:介绍了小方还连铸机结晶器振动液压系统存在的跳振、油温过高和压力冲击大等问题,通过分析结晶器液压系统原理,探究故障产生因素,提出解决方案。重点采用理论计算、AMEsim数值仿真,从、溢流阀、负载的流量匹配和压力匹配角度,分析恒压变量泵不能有效变量、液压油经溢流阀溢流、油液温度不可控的原因,提出增加蓄能器,减小泵排量方案,并得出泵最大排量和各参数设置合理值。将改进方案在9#小方坏还连铸机上应用,生产运行实践证明改进优化成效显著,可推广应用。关键调:小方坏连铸机;结晶器:振动:液压系统

中图分类号:TH137

文献标志码:A

文章编号:1002-2333(2016)10-0148-04

Improvement and Optimization of Vibration Hydraulic System for Mould Oscillation Drives of Small Billet Caster

WANGQuye',TUChen',ZHANGXiaoyong

(1Jiangsu Shagang Group Co, Ld, Zhangjiagang 215625, China;2.Shaoguan Hydraulie Components Co,Ld,Shaoguan 512027,China)

Abstract:This paper introduces some problems in the vibration hydraulic system of mould oscillation drives of small billet caster, such as jump vibration, high oil temperature and pressure impact, By analyzing the principle of mould's hydraulic system, the failure factors are inquired. Then corresponding solving plans are proposed. Theoretical calculating and simulation analysis in AMEsim are conducted. We study the flow matching and pressure matching among pumps,relief valves and loads to analyze the reasons that the constant pressure variable pump cannot effectively change its flow, the ports of relief valves always open and the oil temperature can not be controlled. The method of increasing the numbers of accumulators and decreasing the pump displacement is proposed. The maximum pump displacement and the reasonable values of each parameter are obtained. The modified project is carried out in the No.9 billet caster. The production practices

indicate that these methods are effective and can be extensively used. Keywords: billet caster, mould; vibration; hydraulic system

0引言

结晶器振动是连铸生产的关键控制工艺,液压伺服系统驱动的结品器振动技术是当前最先进技术之一1-"。某厂7#1x6流小方坏连铸机的结晶器振动采用该技术,可实现非正弦规律振动,报幅、频率等工艺参数在线无级调节。该液压系统同时承担结晶器在线更换时设备的进出、锁紧及定位功能。由于液压系统的设计缺陷及工况恶劣,技术人员难以近距离检查维护,存在运行不稳定、故障率高、恢复时间长等间题,针对这些不足,从设计选型、环境

控制等方面进行改造优化,效果较好。小方还连铸结晶器液压系统工作原理

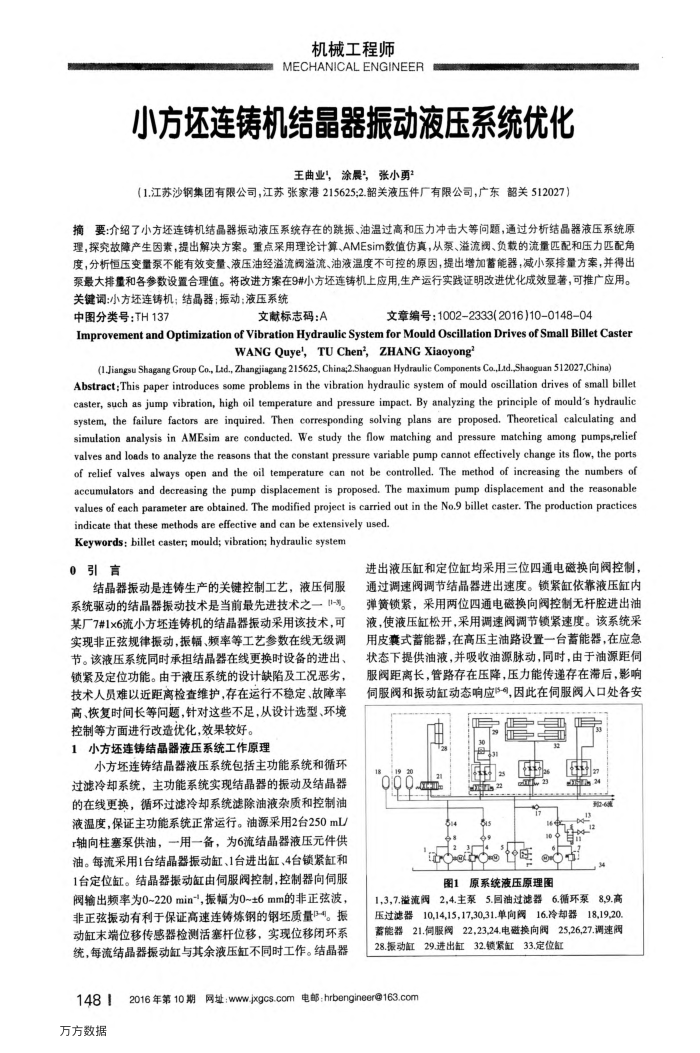

小方坏连铸结品器液压系统包括主功能系统和循环过滤冷却系统,主功能系统实现结晶器的振动及结晶器的在线更换,循环过滤冷却系统滤除油液杂质和控制油液温度,保证主功能系统正常运行。油源采用2台250mL/ r轴向柱塞泵供油,一用一备,为6流结晶器液压元件供油。每流采用1台结晶器振动缸、1台进出缸、4台锁紧缸和 1台定位缸。结晶器振动缸由伺服阀控制,控制器向伺服阀输出频率为0~220min",振幅为0~±6mm的非正弦波,非正弦振动有利于保证高速连铸炼钢的钢坏质量4。振动缸末端位移传感器检测活塞杆位移,实现位移闭环系统,每流结晶器振动缸与其余液压缸不同时工作。结晶器

进出液压缸和定位缸均采用三位四通电磁换向阀控制通过调速阀调节结晶器进出速度。锁紧缸依靠液压缸内弹簧锁紧,采用两位四通电磁换向阀控制无杆腔进出油液,使液压缸松开,采用调速阀调节锁紧速度。该系统采用皮囊式蓄能器,在高压主油路设置一台蓄能器,在应急状态下提供油液,并吸收油源脉动,同时,由于油源距伺服阀距离长,管路存在压降,压力能传递存在滞后,影响伺服阀和振动缸动态响应3-,因此在伺服阀入口处各安

UUL

U

50e

98

啡

.2

@o

图1原系统液压原理图

1,3,7.溢流阀2,4.主泵5.回油过滤器6.循环泵8,9.高压过滤器10,14,15,17,30,31.单向阀16.冷却器

号18,19,20

蓄能器21.伺服阀22,23,24.电磁换向阀25,26,27.调速阀 28.报动缸29.进出缸32.锁紧缸33.定位缸

14812016年第10期网址:www.jxgcs.com电邮:hrbengineer@163.com 万方数据

上一章:液压滚切剪电液伺服协同控制研究

下一章:新型JC25液压盘刹绞车的研制