蒲石河300MW大型抽水蓄能机组轴系安装及轴线调整

内容简介

2012年6月下

2012年6月下第41卷

第367期

施工技术

CONSTRUCTIONTECHNOLOGY

蒲石河300MW大型抽水蓄能机组

轴系安装及轴线调整

王仲陆,周翰青,黄海臣

(武警水电第二总队八支队,福建漢门

361009)

【摘要】确石河抽水蓄能电站采用单机容量为300MW立轴单级混流可逆式水泵水轮发电机组,伞式结构,整个机组轴线为刚性连接,轴系各部分加工及安装精度要求高。介绍抽水蓄能电站机组轴系各部件的结构,论述了发电电动机组轴系各部件、推力轴承、推力头的安装工艺和机组整体盘车及轴线调整的实践。通过对机组联轴及轴线

的调整,经机组运行实测显示,3号与4号机组运行效果良好。【关键调】水电站:抽水蓄能机组;安装;轴系;调整

【中图分类号】TU758;TM312

【文献标识码]A

[文章编号】1002-8498(2012)12-0015-04

ShaftingInstallationandAxisAdjustmentfor3ooMWPumped

StorageUnitofPushihePumpedStoragePowerStation

WangZhonglu,ZhouHanqing,Huang Haichen

(No.8 Detachment, No.2 Hydropower Force of Armed Police, Xiamen, Fujian361009, China)

Abstract:The 300MW pump storage units are adopted in Pushihe Pumped Storage Power Station with umbrella-shaped structure. The whole unit axis is rigid eonnection, and the processing and installation accuracy of each part of shafting is high. The structure of shafting components for pumped storage units are introduced. The practices in shafting components of pumped units, thrust bearing, installation of thrust cone and integral barring as well as axis adjustment are discussed. After shafting installation and axis adjustment for pumped storage units, unit 3 and unit 4 in Pushihe Pumped Storage Power Station are operating satisfactorily

Key words:hydroelectric power stations; pumped storage unit; installation; shafting; adjustment 1工程概况

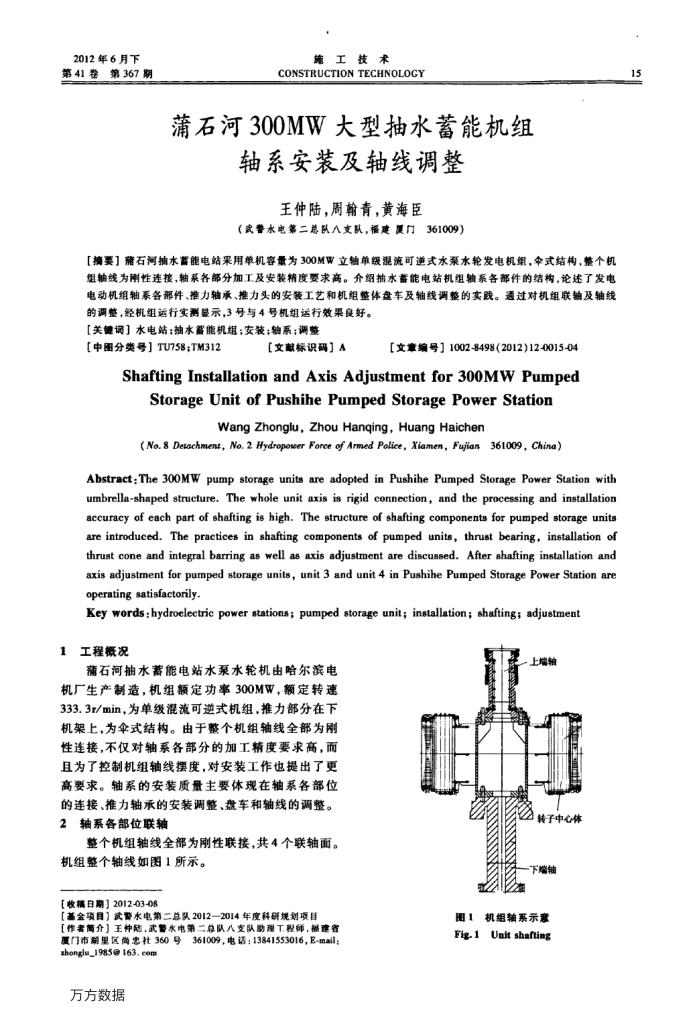

蒲石河抽水蓄能电站水泵水轮机由哈尔滨电机厂生产制造,机组额定功率300MW,额定转速 333.3r/min,为单级混流可逆式机组,推力部分在下机架上,为伞式结构。由于整个机组轴线全部为刚性连接,不仅对轴系各部分的加工精度要求商,而且为了控制机组轴线摆度,对安装工作也提出了更高要求。轴系的安装质量主要体现在轴系各部位的连接、推力轴承的安装调整、盘车和轴线的调整。 2

轴系各部位联轴

整个机组轴线全部为刚性联接,共4个联轴面。

机组整个轴线如图1所示。【收稿日期】2012-03-08

【基金项目】武警水电第二总以2012—2014年度科研规划项目

【作者简介】王仲陆,武警水电第二总队八支队助理T.程师,福建省厦门市别里区尚惠社360号361009,电话:13841553016,E-mail:

zhonglu_1985@163. com 万方数据

上辆

转子中心体下端轴

图1机组轴系示意 Fig.1 Unit shafting

15