1.2 Mt∕a延迟焦化装置油气线结焦现象分析

内容简介

24

24陈油与化工

REFINING AND CHEMICAL INDUSTRY

1.2Mt/a延迟焦化装置油气线结焦现象分析

徐先财,魏文,张灵

(乌鲁本齐石化公司炼油厂.新疆乌鲁本齐830019)

摘要:乌鲁本齐石化公司1.2Mt/a延退焦化装置连续运行2a后,由于焦炭塔大油气线结焦严重.导致焦炭塔压力升高,影响到装置正常生产。通过对该装置大油气线结焦现象分析,结合装置现状和

运行过程中存在的间题,提出相应的优化措施,收到良好的效果。关键词:延迟焦化装置;油气线;结焦;急冷油

中图分类号:TE624.32

文献标识码:B

文章编号:16714962(2016)02002403

第27卷

Analysisof cokingphenomenoninoil&gaspipelinesof1.2Mt/adelayedcoker

Xu Xiancai,Wei Wen,Zhang Ling

(Urumchi Petrochemical Company Oil Refinery , Urumchi 830019, China)

Abstract: After continuous operation of 2 years of the 1.2 Mt/a delayed coker in Urumchi Petrochemical Company, the coking in large oil & gas pipelines of coke tower was severe, which caused the coke tower pressure risen and influenced normal operation of the unit. By analyzing the coking phenomenon in the large oil & gas pipelines , combining the status quo of the coker and the problems existed in operation, the relevant optimization measures was put forward, good result was obtained.

Keywords: delayed coker; oil & gas pipelines ; coking: quenching oil

延迟焦化工艺是重油加工的主要工艺,在原

油加工中发挥差重要的作用。延识售化装置集益塔大油气线结焦现象是国内同类装置中普遍都存在的一个问题]。乌鲁木齐石化1.2Mt/a延迟焦化装置自开工以来,大油气线压降逐渐增大,从0上升至0.06MPa。为保证正常操作塔压(0.15MPa),装置每个月都要对大油气线塔口处进行清焦。

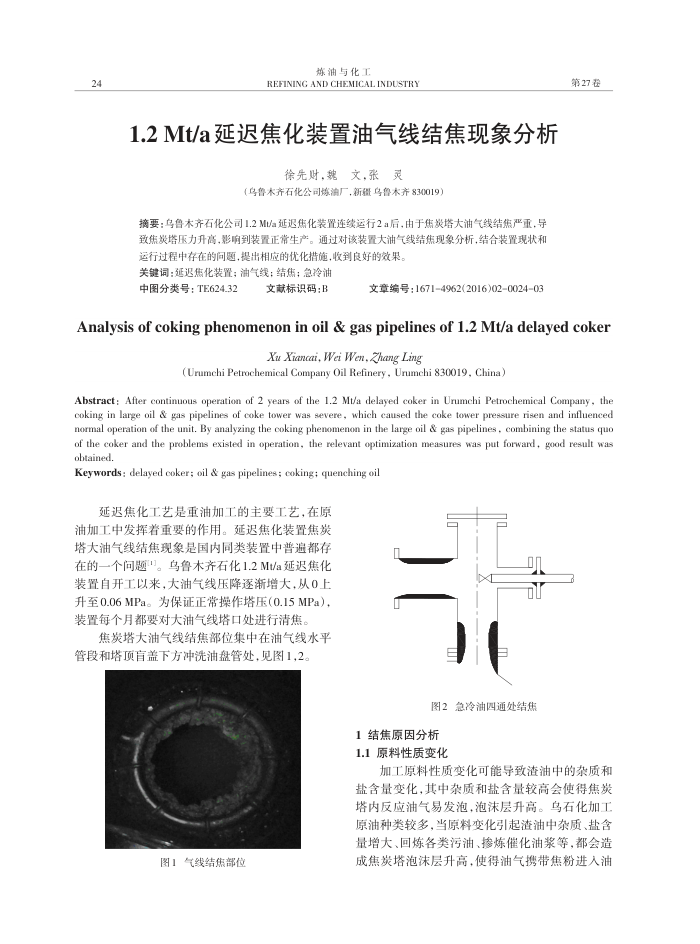

焦炭塔大油气线结焦部位集中在油气线水平管段和塔项盲盖下方冲洗油盘管处,见图1,2。

图2急冷油四通处结焦

1结焦原因分析 1.1原料性质变化

加工原料性质变化可能导致渣油中的杂质和盐含量变化,其中杂质和盐含量较高会使得焦炭塔内反应油气易发泡,泡沫层升高。乌石化加工原油种类较多,当原料变化引起渣油中杂质、盐含量增大、回炼各类污油、掺炼催化油浆等,都会造

图!气线结焦部位

成焦炭塔泡沫层升高,使得油气携带焦粉进人油

上一章:超重力技术在TEG脱水中的应用研究

下一章:固定床催化重整装置绿色停工方案探讨