您当前的位置:首页>论文资料>往复压缩机活塞杆开裂失效分析

内容简介

往复压缩机活塞杆开裂失效分析朱丽红

往复压缩机活塞杆开裂失效分析朱丽红(沈阳鼓风机集团股份有限公司,辽宁沈阳110869)

故障分析 Fat Amalysis

[摘要]:某往复压缩机上的活塞杆在用户服投半年后,在摩擦面上出现裂纹。通过低倍酸没检测、硬度检测、金相组织检测等手段对其进行了失效分析。结果表明:活塞杆在高频萍火过程中由于感应圈非正常停留造成萍火层高、中温国火,由此导致洋火面组织和硬度差异,泽硬层在组织应力及热应力的作用下形成微裂效。该象纹在后续磨加工及使用过程中进一步扩展而导致零件失效。

[关键词]:活塞杆;聚纹;高频津火

中图分类号:TH457

文献标志码:B

文章编号:1006-2971(2016)01-0059-03

AnalysisoftheFractureFailureinReciprocatingCompressorPistonRod ZHU Li-hong

(Shenyang Blower Works Group Corporation, Shenyang 110869, China)

Abstract:The cracks on the piston rod friction surface of a reciprocating compressor were found in the user service after six months. This failure analysis is carried out through the low acid leaching test, hardness test and microstructure examination in this paper. The results show that in the high frequency quenching process, the induction coil of the piston rod stay abnormal, so make the quenching surface undergo tall or medium temperature tempering, so the structure and hardness of the quenching surface are all different, Under the stress action of thermal and the organization of the hardening layer, the micro cracks are foming. The crack will be followup

and further expansion in using process and at last causethepart failure Key words: piston rod; crack; high frequency quenching

1引信

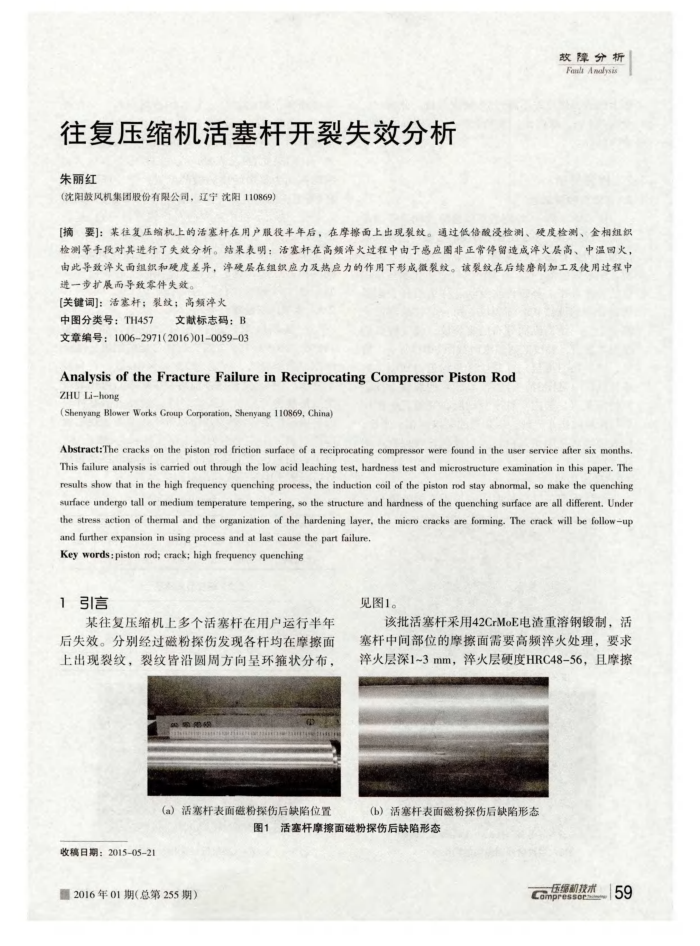

某往复压缩机上多个活塞杆在用户运行半年后失效。分别经过磁粉探伤发现各杆均在廉擦面上出现裂纹,裂纹皆沿圆周方向呈环箍状分布,

(a)活塞杆表面磁粉探伤后缺陷位置

见图1。

该批活塞杆采用42CrMoE电渣重溶钢锻制,活塞杆中间部位的摩擦面需要高频率火处理,要求淬火层深1~3mm,淬火层硬度HRC48-56,且摩擦

(b)活塞杆表面磁粉探伤后缺陷形态

图1活塞杆摩擦面磁粉探伤后缺陷形态

收稿日期:2015-05-21

2016年01期(总第255期)

Cm质绳机技术_59

上一章:往复压缩机级间管路的振动研究

下一章:双螺杆机械增压器变形计算与模态分析