您当前的位置:首页>论文资料>固溶时效提高ZTC4钛合金铸件性能研究

固溶时效提高ZTC4钛合金铸件性能研究

内容简介

Jun.2015 Vol.64No.6

Jun.2015 Vol.64No.6园

造

铸

FOUNDRY

固溶时效提高ZTC4钛合金铸件性能研究

莫晓飞",郭仲贤1,范世玺",王金昭2

(1.北京航空材料研究院,北京100095;2.中国石油吉林石化公司电石厂,吉林省吉林132022)

· 563 ·

摘要:通过对力学性能异常某批次ZTC4钛合金骨架铸件化学成分分析,发现该批次铸件氧含量偏低是造成铸件力学性能不合格的根本原因。采用不同相区氩气冷却固溶处理后,发现经过两种固溶工艺处理后的铸件微观组织均为魏氏组织,都存在α'马氏体、晶界α。晶界都得到不同程度细化。β相固溶后,铸件晶粒明显粗大。β相区固溶时效

后钛合金铸件强度较α+β两相区固溶时效高,但塑性有所降低。较快的冷却速度条件下,铸件固溶后易变形。关键词:ZTC4;钛合金铸件;固溶时效;氩气;力学性能

中图分类号:TG146.2*3

文献标识码:A

文章编号:1001-4977(2015)06-0563-05

Study on Improvement of Properties of ZTC4

TitaniumAlloybySAT

MOXiao-fei',GUO Zhong-xian',FAN Shi-xi',WANG Jin-zhao(1. Beijing Institute of Aeronautical Materials, Beijing 100095, China;

2. Calcium carbide Factory of Petro China Jilin Petrochemical Company, Jilin 132022, Jilin, China)

Abstract:The analysis of chemical compositions of casting shows that a batch of ZTC4 titanium casting has lower tensile properties that were caused by lower oxygen. The ST (solution treatment) cooled by the argon was carried out at different phase zone. The microstructures of castings after ST were Widmanstaten structure, they both had α'martensite, grain boundary α, the grain boundaries were both refined after ST. The grain of the casting was coarse after BST(Bete solution treatment). The casting has higher tensile properties after BST than ABST(Alpha-beta solution treatment), but it has lower plasticity. The ZTC4 titanium casting was easy to be deformed due to the higher coolingrate in the course ofST.

Key words: ZTC4; titanium casting; solution and aging treatment; argon; mechanical properties

Ti6AI4V铸造合金具有良好的铸造性能,适用于制造尺寸较大,形状复杂的薄壁铸件,近二十年精密铸造技术的不断发展,推动了钛铸件的大批量生产,扩大了大型复杂、薄壁钛铸件在航空、航天技术领域的应用,随着高性能飞机和发动机、火箭等的出现,钛铸结构件大量采用了Ti6AI4V合金。

1铸件力学性能异常原因分析

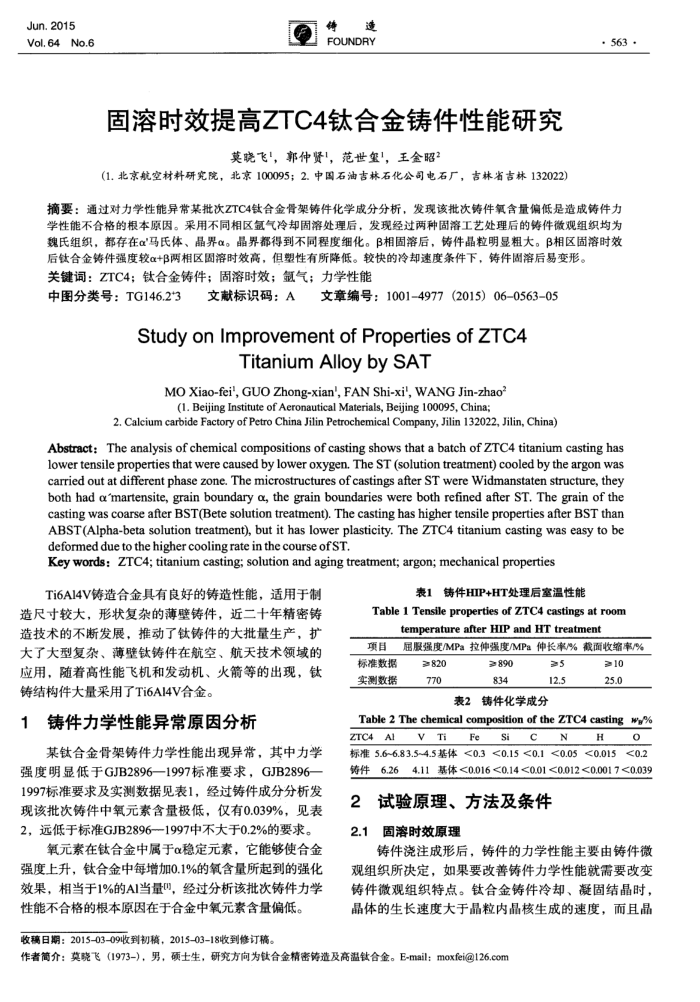

某钛合金骨架铸件力学性能出现异常,其中力学强度明显低于GJB2896一1997标准要求,GJB2896-1997标准要求及实测数据见表1,经过铸件成分分析发现该批次铸件中氧元素含量极低,仅有0.039%,见表 2,远低于标准GJB2896-1997中不大于0.2%的要求。

氧元素在钛合金中属于α稳定元素,它能够使合金强度上升,钛合金中每增加0.1%的氧含量所起到的强化效果,相当于1%的AI当量,经过分析该批次铸件力学

性能不合格的根本原因在于合金中氧元素含量偏低。收稿日期:2015-03-09收到初稿,2015-03-18收到修订稿。

表1铸件HIP+HT处理后室温性能

Table 1 Tensile properties of ZTC4 castings at room

temperature after HIP and HT treatment

项目标准数据实测数据

屈服强度/MPa拉伸强度/MPa伸长率/%截面收缩率/%

820 770

890 834

>5 12.5

表2铸件化学成分

>10 25.0

Table 2 The chemical composition of the ZTC4 casting wg%

ZTC4

V

V

Ti

Fe

Sic

N

H

o

<0.3≤0.15 ≤0.1 <0.050.015

标准5.6~6.83.5~4.5基体

5<0.2

铸件6.26

2 2.1

4.11基体≤0.016 <0.14<0.01<0.012<0.0017<0.039

试验原理、方法及条件固溶时效原理

铸件浇注成形后,铸件的力学性能主要由铸件微

观组织所决定,如果要改善铸件力学性能就需要改变铸件微观组织特点。钛合金铸件冷却、凝固结晶时,晶体的生长速度大于晶粒内晶核生成的速度,而且晶

作者简介:莫晓飞(1973-),男,硕士生,研究方向为钛合金精密铸造及高温钛合金。E-mail:moxfei@126.com