您当前的位置:首页>论文资料>一种新型轴承径向游隙检测与分选装置

内容简介

ISSN10003762 CN41 1148/TH

ISSN10003762 CN41 1148/TH轴承

2016年7期 Bearing2016,No.7

一种新型轴承径向游隙检测与分选装置

郑晓峰",陆斌超',应正平2

t9-19

(1.浙江机电职业技术学院机械工程学院,杭州310053;2.湖州出入境检验检疫局,浙江潮州313200)摘要:研制了轴承径向游隙自动检测与分选装置,可实现自动送料、自动检测与自动分选。该装置机械结构包括送料机构、夹紧机构、顶旋机构和分选机构;控制系统以STC12c5a60S2单片机为核心,采用C语言编制控制程序;测量系统由激光传感器构成,以LabVIEW编制显示界面,用于数据的采集、显示与分析。试验表明,研制

的轴承径向游隙自动检测与分选装置能够快速精确地对轴承径向游隙进行检测与分选。关键词:滚动轴承:径向游隙:检测;分选;激光传感器;LabVIEW

中图分类号:TH133.33;TP23

文献标志码:B

文章编号:10003762(2016)07-006104

ANewTypeDetectionandSortingDeviceforRadialClearanceof

Bearings

Zheng Xiaofeng', Lu Binchao', Ying Zhengping

(1. School of Mechanical Engineering, Zhejiang Institute of Mechanical and Electrical Engineering,Hangzhou

310053, China;2. Huzhou Entry Exit Inspection and Quarantine Bureau, Huzhou 313200, China)

Abstract: The automatic detection and sorting device is developed for radial clearance of bearings, which realize auto-matic feeding, detection and sorting., The mechanical structure of device includes feeding mechanism, clamping mecha-nism, top spin mechanism and sorting mechanism. The core of control system is microcontroller STC12e5a60S2, and the control program is programmed by C language. The detection system is composed of a laser sensor, and the Lab VIEW is programmed to display interface for data acquisition, display and analysis. The experiments demonstrate that the detection and sorting for radial clearance of bearings is quickly and accurately realized by developed automatic de tection and sorting device.

Key words: rolling bearing; radial clearance; detection; sorting; laser sensor; LabVIEW

径向游隙影响轴承的运转精度、寿命、振动与噪声等,是轴承必检项目(1-2)。目前,轴承径向游隙的检测方法有塞尺检测法、压铅检测法、专用测量仪(如X093JB)、在线自动检测等,塞尺法和专用测量仪的成本低,但效率不高,且存在人为读数误差:在线自动检测能进行快速准确地测量,但成本大,且在线抽检的轴承仍需手动检测[3-4]。

为解决上述问题,研制了一种新型轴承径向游隙自动检测与分选装置,可实现轴承径向游隙的自动检测与分选(适用于外径15~120mm的各类滚

收稿日期:2016-0203;修回日期:2016-04-18 基金项目:浙江省教育厅科研项目(Y201534342)

作者简介:郑晓峰(1985一),男,浙江台州人,研究方向为检测技术与机械自动化,E-mail:hyzxf2001@163.com。

万方数据

动轴承),大大提高轴承径向游障的检测效率。

机械结构

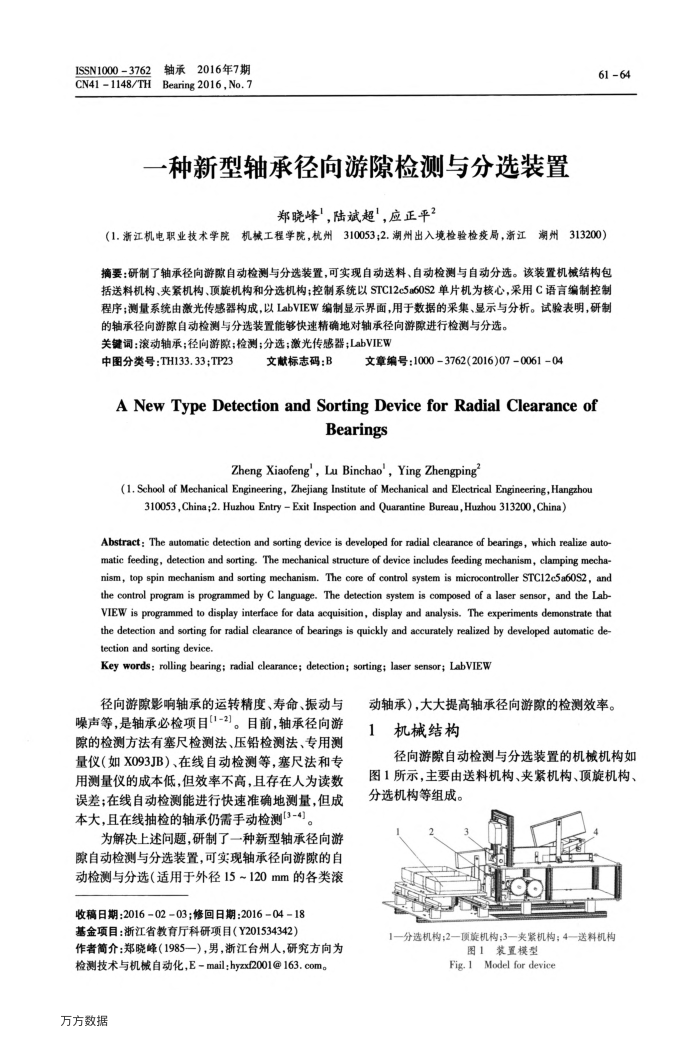

径向游隙自动检测与分选装置的机械机构如图1所示,主要由送料机构、夹紧机构、顶旋机构分选机构等组成。

1一分选机构;2—顶旋机构;3—夹紧机构;4—送料机构

图1装置模型

Fig. 1Model for device

上一章:高速铁路轴箱轴承用润滑脂耐久性试验研究

下一章:一种绝缘轴承绝缘电阻测试方法