您当前的位置:首页>论文资料>管道内表面缺陷的涡流检测方法

内容简介

2014年第10期

2014年第10期仅表技术与传赢器 InstrumentTechniqueandSensor

管道内表面缺陷的涡流检测方法

杨理践,郭晓婷,高松痴

110870)

(沈阳工业大学信息科学与工程学院,辽宁沈阳

2014 No. 10

摘要:针对管道检测中内、外壁缺陷难以区分的问题,采用提高检测线圈分辨率的涡流检测方法,实现了管道内壁缺陷的识别,解决了内外缺陷确认难题。利用ANSYS仿真软件建立了线遇探头和待测管段的实体模型,通过仿真,得出了缺陷几何尺寸对线圈探头产生醛场的变化规律,仿真中通过改变线圈探头的数、缺陷深度等条件,分析了轴向方向磁感应强度的特征。同时结合仿具分析结果,开发了线围探头实验装置,并利用该装置实现了45锅板的检测。试验结果表

关键词:涡流检测;涡流传感器;有限元仿真;表面缺陷;磁感应强度

中图分类号:TG115.28

文献标识码:A

文章编号:10021841(2014)10007804

MethodoftheEddyCurrentTestingtoPipelineInnerSurfaceDefects

YANG Li-jian, GUO Xiao-ting,GAO Song-wei

(School of Information Science and Engineering,Shenyang University of Technology,Shenyang 110870, China)

Abstract : Aiming at the difficulty of defects between the inner and outer wall distinguish of the pipeline inspection, the method of eddy current detection was used to improve the detection coil resolution. The recognisation of pipeline inner defects was realized and the problem of confiming the intermal and extermal defects was resolved. The solid model of the coil probe and the pipeline sec-tion were built by the ANSYS simulation software, The geometry defects generated a magnetic field variation to the coil probe and was obtained through the simulation. The characteristic of the magnetic induction intensity of the axial direction was analyzed by changing the number of turms of the coil probe and defect depth. At the same time,the simulation results were combined to develop a coil probe experimental device, And the 45 # steel was detected using the device, Experimental results show that the peak differ-ence of the output voltage signal is accurate to millivolt level in the defects of the steel sheet. The level of precision can be achieved to detect the pipe wall defects.

Key words:eddy current testing;eddy current sensor;finite element simulation;surface defects;magnetic induction

引言

目前,涡流检测技术对于管道内外壁上的缺陷的灵敏度是相同的,但对管壁内外缺陷进行区分时却无能为力,因此,为提高辨别管道内外缺陷的分辨率,需设计辅助线圈探头来辨别管道的内外缺陷。

检测线圈是涡流探头的重要组成部分,优化设计线圈的几何参数和形状,可以提高涡流传感器的分辨率"]。从线圈探头在空间产生的磁场分布情况及磁感应强度大小方面分析,仿真分析线圈几何参数对管道内表面缺陷影响,优化其几何参数制作了线圈探头对被测试件表面的深度分别为2mm、4mm、 6mm的缺陷以及背面缺陷进行检测,检测输出信号可以对管道

内外缺陷进行辨别。 1涡流检测基础理论

1.1涡流检测管道内表面缺陷一般原理

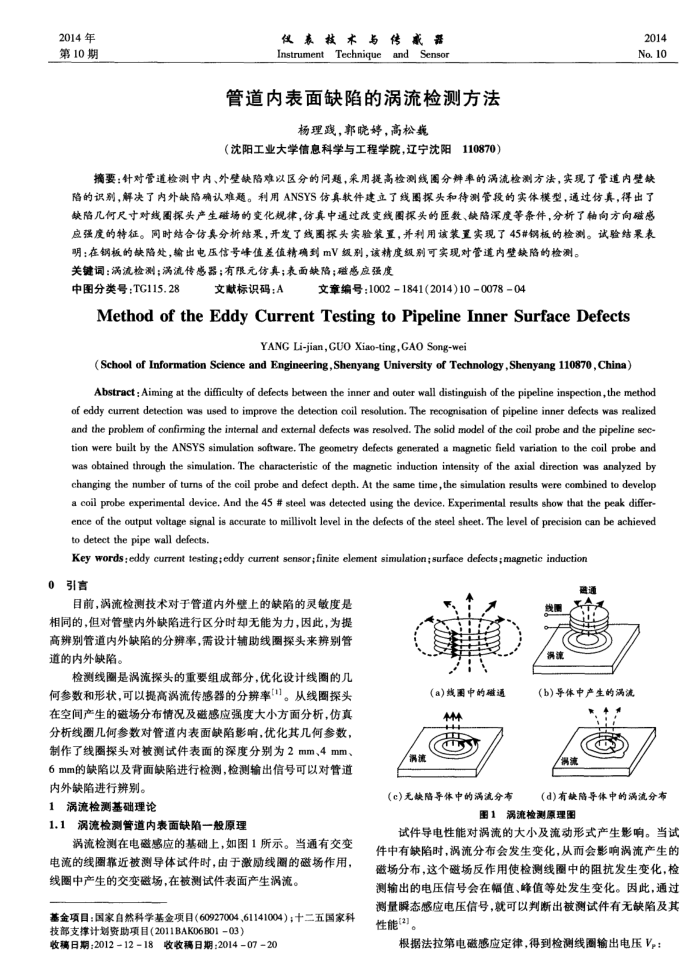

涡流检测在电磁感应的基础上,如图1所示。当通有交变电流的线圈靠近被测导体试件时,由于激励线圈的磁场作用,线圈中产生的交变磁场,在被测试件表面产生涡流。

基金项目:国家自然科学基金项目(60927004、61141004);十二五国家科技部支撑计划资助项目(2011BAK06B01-03)

收稿日期:2012-12-18收收稿日期:2014-07-20

/涡流

(a)线图中的磁通

(c)无缺陷导体中的涡流分布

满新

通通

(b)导体中产生的涡流

*

/涡流

(d)有缺陷导体中的涡流分布

图1涡流检测原理图

试件导电性能对涡流的大小及流动形式产生影响。当试件中有缺陷时,涡流分布会发生变化,从而会影响涡流产生的磁场分布,这个磁场反作用使检测线圈中的阻抗发生变化,检测输出的电压信号会在幅值、峰值等处发生变化。因此,通过测量瞬态感应电压信号,就可以判断出被测试件有无缺陷及其性能(2)。

根据法拉第电磁感应定律,得到检测线圈输出电压Vp:

上一章:输油管道环境敏感地区线路阀室设置研究

下一章:基于多传感器的管道泄漏检测装置设计