您当前的位置:首页>论文资料>高含硫气田水处理工艺优化改造及效果分析

内容简介

第36卷第2期(2017.02)

第36卷第2期(2017.02)高含硫气田水处理工艺优化改造及效果分析王增1刘涛主

彭龙,

张中1陈露2

集输处理

摘要:为降低普光气田1"水处理站水处理系统硫化氢泄漏风险,提高药剂利用效率,确保注水水质合格,采取了增设PH值调节剂加注系统控制来水PH值以提高气浮除硫效果,调整除硫剂加注口位置降低气浮池硫化氢含量以降低硫化氢泄漏风险,增设污水缓冲罐控制来水平稳性,增设药剂混合器增加药剂混合反应时间,增设pH值和悬浮物在线监测仪时时监测水处理状态等措施。上述措施控制了来水平稳性,实现了药剂加注的自动化控制,提高了药剂的利用效率,泄漏和环境污染问题得到了有效控制,处理后的污水水质达到了油田注水的标准。

关键词:高含硫气田;污水处理;缓冲罐;除硫剂;pH值 Doi:10.3969/j.issn.1006-6896.2017.2.011

TheAnalysis of WaterTreatment Process Reformationin HighSulfurGasField Wang Zenggang,LiuTaoPeng Long,Zhang Zhong,Chen Lu

Abstract:In 1water treatment station,Puguang Gas Field, pH value regulator system was added to improve the gas flotation sulfur removal effect so that the pH value of supplied water was under con-trol. This act reduced the risk of hydrogen sulfide leakage, improved the chemical efficiency and en-sured the injection water quality. Meanwhile, the entrance of sulfur removal agent was adjusted to de crease the content of sulfide hydrogen, which helped to lower gas leakage risk; a waste water buffer rank was introduced to control stabilization of incoming water; a agents mixer was used to prolong the reaction time; an online monitor of pH value and suspended matter was newly available to monitor the water treatment condition.All these acts above took the control of the automatic chemical filling and improved the performance efficiency of the chemical. Thus, the hydrogen sulfide leakage risk and en vironment pollution are under control, and the quality of the waste water met the standard of water in jection in oilfield.

Key words: high sulfur gas field; waste water treatment; buffer rank; sulfur remover; pH value

普光气田是国内已投人开发的最大的整装海相气田,产出原料气中硫化氢体积分数为12.31%~ 17.05%,二氧化碳浓度7.9%~10.53%,产出水中二价硫离子浓度为600mg/L以上。日产水量接近 600m,高含硫污水处理难度极大。

1水处理站作为普光气田污水处理的主要站场,2009年10月投产,至2015年已经连续运行了 6年,实际生产中暴露出诸多间题,存在很大的安全隐患和不合理的处理工艺过程,处理工艺流程函需优化改造。

污水来源及水质分析

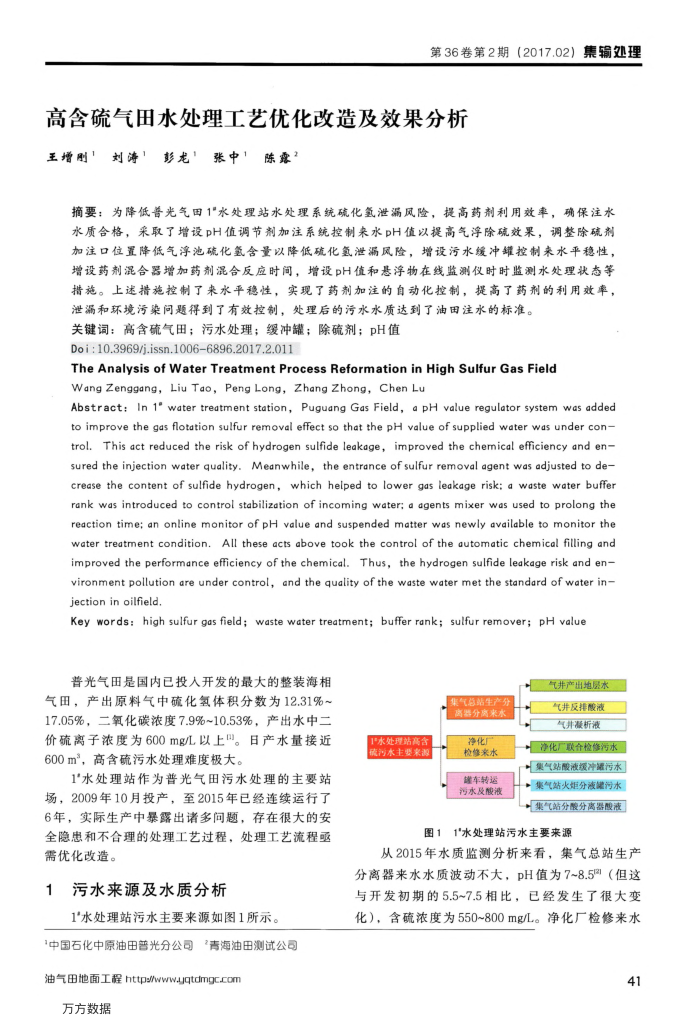

1'水处理站污水主要来源如图1所示。

1中国石化中原油田普光分公司“青海油田测试公司

油气田地面工程https/www.uqtdimgc.com 万方数据

清水处理站高舍中水主费来

离金分离小

净化厂检修水

罐车转运污水及酸液

气井产出地层水气井反排酸液气井凝析液

净化厂联合检修污水集气站酸液缓冲罐污水集气站火炬分液罐污水集气站分酸分离器酸液

图11"水处理站污水主要来源

从2015年水质监测分析来看,集气总站生产分离器来水水质波动不大,pH值为7~8.5(但这与开发初期的5.5~7.5相比,已经发生了很大变化),含硫浓度为550~800mg/L。净化厂检修来水

41

上一章:长输油管道砂沉积模拟实验及临界流速计算分析

下一章:降低阀室接地电阻的快速确定方法