您当前的位置:首页>论文资料>酸性气井井筒腐蚀控制技术研究

内容简介

76

76石油与天然气化工

CHEMICAL ENGINEERING OF OIL & GAS

酸性气井井筒腐蚀控制技术研究袁曦1肖杰张碧波”王星’朱庆2蔡德强2王萌? 1.中国石油西南油气田公司天然气研究院2.中国石油西南油气图公司蜀南气矿

2017

摘要采用高温高压离蚀挂片、气田水化学分析、多臂并径仪测井等方法,在含H,S/CO酸性气并中,研究了缓蚀剂对并下油管的保护效果。试验结果表明,评选的缓蚀剂防腐效果良好,并下加入缓蚀剂4年后,全油管平均扁蚀速率为0.04mm/a,房蚀速率远低于扁蚀控制指标0.1mm/a;油管腐蚀主要集中在井简上部和底部。

关键调井筒硫化氢二氧化碳腐蚀缓蚀剂

中图分类号:TE988.2

文献标志码:A

DOI: 10.3969/j.issn.1007-3426.2017.01.015

Studyonwellborecorrosioncontroltechnologyinsourgaswells Yuan Xi',Xiao Jie',Zhang Bibo',Wang Xing',Zhu Qing',Cai Deqiang',Wang Meng 1. Research Institute of Natural Gas Technology, PetroChina Southuest Oil and Gasfield Com pany,

Chengdu, Sichuan, China; 2. Southern Sichuan Gas District, PetroChina Southwest

Oil and Gasfield Company, Luzhou, Sichuan, China

Abstract: Using methods of corrosion coupon in high temperature and high pressure, chemistry analysis of gas water and multi-arm caliper logging tool, the application effects of corrosion inhibitor were studied on H, S/CO; gas well. Test resuilts showed that the selected corrosion inhibitor has good effect of anti-corrosion, after addition of corrosion inhibitor for 4 years, the corrosion rate of full tubing was O. O4 mm/a, lower than 0. 1 mm/a corrosion control standard; the corrosion areas were mainly concentrated at the top and bottom of the tubing.

Keywords;wellbore,H,S,COg,corrosion,corrosioninhibitor

井篇油管的服役可靠性是油田安全开发中至关重

要的环节,由于我国逐渐加大了含H,S/CO:酸性气田的开发力度,油管的服役环境越发恶劣,给井下安全生产带来不确定性。近年来,对井下油管腐蚀的研究主要集中于单一CO:或HS环境[2-11,而对同时含 H,S/CO,环境的研究相对较少。项目组针对含H,S/CO;酸性气井的开采工况,采用高温高压腐蚀挂片,优选适用缓蚀剂,并结合现场气田水化学分析、多臂井

径仪等井简腐蚀监测手段,研究了井下缓蚀剂的应用效果,对含H,S/CO:酸性气井的井筒腐蚀控制具有

一定参考价值。 1试验

1.1基本情况

试验气井是一口含H,S/COz的酸性气井,天然气中HS质量分数为2.15%,CO,质量分数为 3.94%,气井基本情况见表1,气田水化学组成见表2。

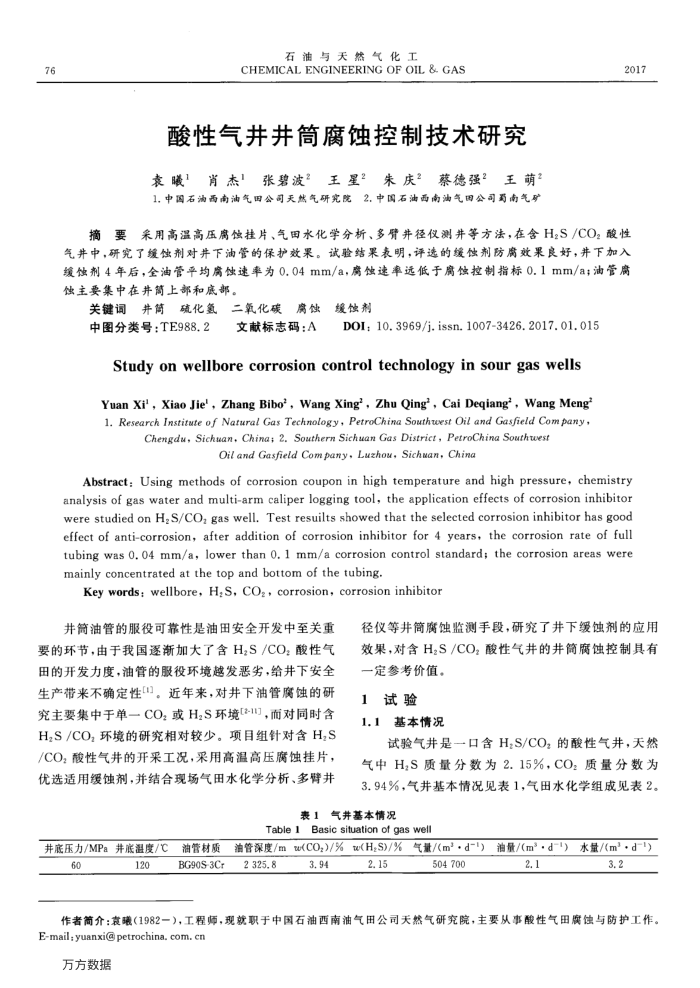

表1气井基本情况

Table1

Basic situation of gas well

井底压力/MPa并底温度/C

油管材质

60

120

BG90S-3Cr

油管深度/mw(CO,)/%w(H,S)/%

气量/(m·d-")

(,-P·")/善(P·)/善联

2325.8

3. 94

2. 15

504 700

2.1

3.2

作者简介:袁曦(1982一),工程师,现款就职于中国石油西南油气田公司天然气研究院,主要从事酸性气田廣蚀与防护工作。 E-mail:yuanxi@petrochina,com.cn

万方数据

上一章:X油藏注气混相驱可行性实验研究

下一章:LNG接收站发热量调整工艺研究及经济评价