改进支持向量机在SLA﹢3﹢D打印模型尺寸误差预测的应用

内容简介

第9期 2017年9月

第9期 2017年9月组合机床与自动化加工技术

Modular Machine Tool & Automatic Manufacturing Technique

文章编号:10012265(2017)09003505

DOI:10. 13462/j. cnki. mmtamt. 2017. 09. 010

改进支持向量机在SLA3D打印模型

尺寸误差预测的应用董雪,江鹏,陈晓波,习俊通

(上海交通大学机械与动力工程学院,上海200240)

No.9 Sep.2017

摘要:采用SLA3D打印机打印不同参数的同一模型,测量成型件模型尺寸参数,并利用改进的LS一 SVM模型对不同参数的成型件尺寸误差进行预测。首先分析主要影响SLA3D打印模型质量的原因,确定四个主要因素:叠层厚度,模型摆放角度和支撑密度,接触点大小。设计试验,采用SLA3D 打印机在此参数下打印,再对打印成型件进行测量确定成型件尺寸信息及尺寸误差,基于已有数据建立改进的LS-SVM模型对不同打印参数下的成型件的尺寸误差进行预测。结果表明模型预测正确率达到92.6471%,改进的LS-SVM相较于原寻优方法及BP神经网络对SLA3D打印尺寸误差预测有良好的效果。

关键词:SLA3D打印;最小二乘支持向量机;打印质量预测

中图分类号:TH164;TG506

文献标识码:A

Improved Least Squares Support Vector Machine (SvM) Used

on Size Error Prediction of SLA 3D Printing Model DONG Xue,JIANG Peng, CHEN Xiao-bo,XI Jun-tong

(School of Mechanical Engineering, Shanghai Jiaotong University, Shanghai 200240,China)

Abstract : SLA 3D printer prints the same model of different structural parameters, and to acquire the size error of different models printed models are measured , finally an improved LS-SVM prediction model is built to predict the size error of model printed on other structural parameters . Firstly four factors that affects quality of the printed model are analyzed including thickness of the printing, the area of touch segment , den-sity of supporters and the angle of the model set . Then an experiment that consists of the different structural parameters is desiged and implemented. Models are measured and size information is got. Then transforming analysis of experimental data into size error and sorting the results with certain tolerance threshold . Finally improved LS-SVM model is built to predict models' size error. Results show that the model prediction accu-racy reached 92.6471% and the improved LS-SVM prediction method works well on error prediction of

SLA 3D printing models than other methods such as the former one and the BP-neural network. Key words: SLA 3D printing; LS-support vector machine (LS-SVM); size error prediction

0

引言

3D打印采用材料积累的加工方法,区别于传统的材料去除工艺,是近些年新兴的一种工业快速成型技术[]。目前的3D打印技术主要有立体平板印刷(SL),选择性激光烧结(SLS/SLM)分层实体造型(LOM)和熔融沉积造型(FDM)[2),其中选择性激光烧结技术以基于激光技术的立体光固化(SLA),激光选取烧结(SLS)为主,本文研究的是基于激光技术的立体光固化(SLA)3D打印。

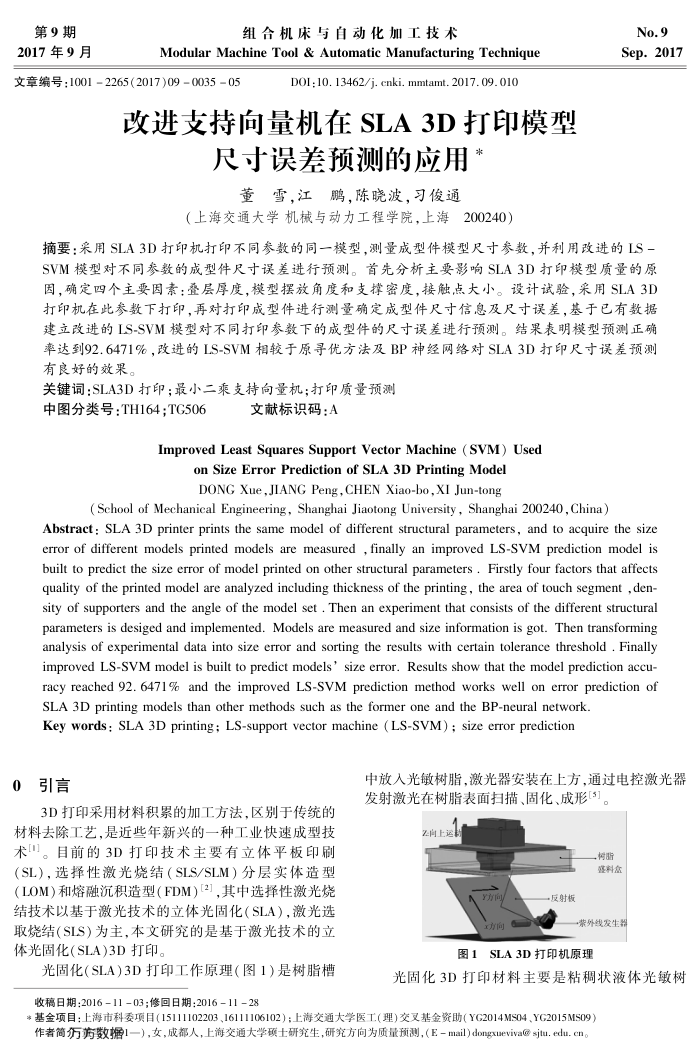

光固化(SLA)3D打印工作原理(图1)是树脂槽收稿日期:2016-11-03;修回日期:2016-11-28

中放入光敏树脂,激光器安装在上方,通过电控激光器发射激光在树脂表面扫描、固化、成形[3。

2-向上运制

树脂盛料盒

反射板

蒙外线发生器

图1SLA3D打印机原理

光固化3D打印材料主要是粘稠状液体光敏树

*基金项目:上海市科委项目(1511110220316111106102);上海交通大学医工(理)交叉基金资助(YG2014MS04,YG2015MS09)作者简纺药数播1—),女,成都人,上海交通大学碳士研究生,研究方向为质量预测,(E-mail)dongxueviva@sjtu.edu.en。